Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

Commodore C16 Restoration – Part 4 - The Deep Clean

Hi all, I have just completed another part of the restoration

of my C16. This time giving it a complete strip down, deep clean, rust removal

and nickel plating using Electrolysis and Electroplating.

In this entry I will show you how to completely strip

the C16 down (including the keyboard) and how I gave my one a complete

makeover.

There is also a youTube clip showing the process from start to finish at the end of this entry.

Tools required:

Soldering Iron

Cutters

Pliers

De-Soldering Tool

Scalpel

Spudger

Steel Ruler

Power Supply

Car Battery

Toothbrush

Ultrasonic cleaner (optional)

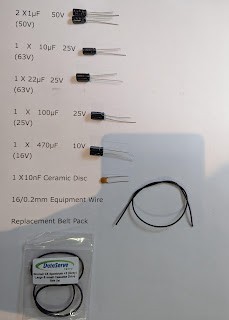

Components and other bits required:

Cotton Buds

IPA Alcohol

Steel Wool

Paper Towel

Washing liquid

Ultrasonic Cleaning fluid

Double Sided Tape

Insulating Tape

In this entry I revisited the electrolysis and

electroplating process I did during my Vic 20 restoration; more details about

that process can be found on YouTube

and in this blog

https://alleged-geek.blogspot.com/2021/08/commodore-vic-20-restoration-part-2.html

So, let’s get started!

Strip down the C16, removing

the motherboard.

Then strip the components from

the lid of the C16 starting with the keyboard.

Remove the 8 highlighted screws

with a medium sized cross headed screwdriver.

Then remove the Power LED from

the lid of the C16.

This is done by removing the

circular retaining clip which holds the LED in place on the underside of the

lid.

Below is a photo of its

location.

I used a pair of pliers to grip

the retaining clip and pull it free from the LED Bezel.

I thought it best to slide the retaining clip all the way along the wires to the PCB connector as losing this would mean that the LED would not be properly secured when refitting.

The Function keys were easy to

remove and I managed them by hand; simply pulling up on the key until it came

free, then storing the key in one tub and the spring in the second tub.

However, the remaining keys

were very hard to free this way so I ended up carefully levering the keys off

the plunger with a medium sized plastic spudger.

All of the keys have a spring

with the exception of the Shift Lock key which is fitted to a spring loaded

switch on the keyboard base. It is worth making a note of this before refitting

the keyboard.

Carry on removing the keys

until you get to the last one, the space bar. The space bar has a long metal

supporting bar which is clipped on to the keyboard housing. Gently pry the key

off from the back at an angle as shown in the photo below.

Here you will see two while

sliders to the left and right ends of the key as well as the supporting bar.

As the clips holding the

supporting bar look a wee bit fragile, gently pull the supporting bar clear

from the clips on the keyboard housing then place the key and springs in their

containers.

Now remove the two wires

connecting the Shift Lock switch to the keyboard PCB. This is done by removing

the insulating tape (which looks remarkably like selotape) then de-soldering

the two wires.

I find that un-insulated wires

such as the two wires here conduct heat a lot quicker than standard insulated

wire so it is a good idea to melt the solder and use either a pair of pliers or

tweezers to lift the wire free from the pins of the switch. This should prevent

you from burning your fingers.

After that, remove the 23! Yes

23!! Small screws which fix the keyboard PCB to the housing. You will require a

small cross headed screwdriver for this as they are really small. Then store

the screws somewhere safe (I used my magnetic mat to hold the screws in

position.

This keyboard PCB looks in

pretty good shape for its age unlike the VIC 20 PCB where I witnessed trace rot

for only the second time in my career.

After that, remove all the key

plungers and store in another container. You should find that they simply fall

out when you turn the housing over with the exception of the Shift Lock Switch

which requires pushing out as shown below.

I then used my ultrasonic

cleaner to clean the keys and springs. The cleaning solution I used for this

purpose was from OCTOPUS which claims to be good for print heads, electrical

components, metal items, small tools, glasses and jewellery.

Note: I appreciate that not

everyone has access to an ultrasonic cleaner so a simple scrub with soapy water

and a toothbrush works just as well (it just takes a bit longer)

Place the keys in the Ultrasonic basket; unfortunately the Space Bar was too long to fit in the basket of my cleaner (but it did fit in the cleaner diagonally without the basket so I cleaned it separately)

Then set the timer to from anywhere between 5 and 10 minutes (I opted for 7 minutes) A thing to note is that the solution will heat up naturally when using an ultrasonic cleaner. If the solution gets too warm this could warp and twist the keys out of shape.

The following pictures show

that the temperature of the solution rose from 16°C to 24°C in as little as 7

minutes.

Place the spacebar in the

ultrasonic cleaner without the basket and give it a clean for 7 minutes, whilst

it is cleaning wipe the excess fluid off the keys with some paper towel to

avoid any ‘watermarks’ as the solution dries naturally.

Once the space Bar has been

cleaned, place the springs into the basket and clean them in the ultrasonic

cleaner for 7 minutes. I managed to dry all the keys with paper towel by the

time the springs were cleaned. After the springs have been cleaned dry them off

with some paper towel and leave all the keys and springs to dry out completely

before refitting the keyboard (I left them to dry out overnight)

With the keyboard, keys and

springs set aside, give the PCB a clean with some 99.9% IPA and a toothbrush to

remove all the old (and new) flux residue.

This tends to leave the PCB

feeling a bit sticky so I tend to go over the PCB with some fresh IPA and a

cotton bud which usually cleans the PCB up pretty well.

The problem when using a cotton

bud on the solder side of the PCB is that the cotton bud gets caught on the

component legs and it leaves cotton fibres between the legs of components. I

find that using a clean dry toothbrush and scrubbing gently usually removes all

the cotton fluff from the PCB.

After the solder side has been cleaned, go over the component side with some IPA and a cotton bud.

I decided to remove the serial number label before cleaning the case of the C16. As you can see from the picture below, the label has 2 folded up corners. My plan was to remove the label and reapply it using double sided tape.

Great care has to be taken when removing the label as they are easily torn. I find that spraying the label with IPA (it really is wonderful stuff) will allow you to peel the label off if you are patient enough to let the IPA soak into the paper backing of the label.

Then start peeling the label

off; peel slowly and when the paper behind the label looks dry add more IPA.

Do this until the label is

completely free from the case.

Then clean the paper backing on

the case with your fingernail.

And a cotton bud.

Then give the bottom of the C16

a wee clean with some IPA and paper towel.

For the next part, I am going

to revisit a technique I did when restoring my VIC 20. For some reason the

modulator lids and RF shields of all my restored Commodores to date all suffer

from rust.

I have heard that you can

simply stop the rust from getting worse by immersing the parts in vinegar but

they would still look ugly and I wanted my C16 to look like new. So I opted to

remove the rust using electrolysis.

My Vic 20 post about this

process goes into greater detail but I will explain the basics here anyway.

You will need the following

equipment/ingredients

Baking Soda or Salt

Water

Plastic Tub

Something to secure the Iron anode

An Iron Anode (I used an old screwdriver)

Car Battery

Cables with croc clips (to fit the battery and attach

to the Anode and rusted part)

Wire Wool (I used a soap filled pad)

You may want to use gloves as well as it is quite a

dirty process.

Below is the wiring Diagram.

I added about 3

tablespoons worth of salt to the small tub.

And about 10

tablespoons worth of salt to the larger tub.

Add water and dissolve

the salt completely.

Then wire up the

circuit as shown in the diagram earlier and plug the positive and negative

connectors into the car battery.

You should see it

reacting almost instantly.

If it doesn’t react

instantly, try adding more salt to the solution (unplug the battery before

adding and dissolving the extra salt)

And whilst

Electrolysis is doing its magic, give the C16 case, bezel and keyboard housing

a clean with some soapy water and a toothbrush.

After cleaning, rinse

each part thoroughly with some fresh water and dry off with some paper towel. I

left the parts to dry out completely overnight along with my keys, springs and

motherboard.

This process took over

an hour and by that time the electrolysis had done its magic. I removed the

parts from the containers and gave the modulator lid and RF Shield a good scrub

with some wire wool.

Now, I could have left

it there but the parts would soon start rusting again so I had a couple of

choices:

1 – I could use the

vinegar technique to prevent the rust from starting or spreading.

Or

2 – I could use electroplating

to coat the metalwork with nickel.

Option 1 is quicker

but from what I have read and seen, the vinegar does stop the rust from

spreading but it will kind of ‘stain’ the metal a deeper colour where it had

been rusting before.

So

I opted for the second

choice as I already have some nickel acetone (stored away safely) which I made

for my VIV 20 Restoration Project.

For details about how

to make your own Nickel Acetone, have a look at the following entry in this

blog.

The wiring diagram for

the electroplating process can be found below.

Now, a wee word of

warning goes out to anyone who wants to try this out… it is a smelly process

which does not always go down well with others in the household. For example,

the last time I tried this, Mrs Geek exploded her wrath upon me; I think the

whole of the North East of Scotland heard her! The ground shook, the air turned

blue and I ran for my life… she really wasn’t happy.

Fearing for my

wellbeing this time round, I decided to close the kitchen door and open all the

windows… before very quietly setting up the equipment.

All was going well

until about 20 seconds into the process when all hell broke loose within Geek

Mansion. Some of the names she called me were truly unflattering (but I

resisted the urge to ask what some of the words meant this time ;)) I think the

tamest word she used was IDIOT but there were loads of expletives before and

after the IDIOT part. Needless to say, she wasn’t too happy with me again. For

the sake of my viewers on youTube, I even removed the audio from that part of

the clip!

Anyhoo! Back to the

electroplating

Connect the positive

wire from the power supply to the nickel anode.

I set the voltage on

my new power supply to 4.5V, and set the current to a maximum of 3A.

Then I poured in the

nickel acetone.

Then I connected the

negative wire to the modulator lid, placed it in the solution next to the

nickel anode.

Then turned the power

supply on and gently wiggled the negative wire to shake off the bubbles being

formed as part of the process from affecting the finish (if left on they can

leave small circles on the metal)

Success, the modulator

lid coated quite well in about 20 minutes

However, the

motherboard PCB RF shield was a wee bit more problematic as the plating process

only appeared to coat the small area beside the nickel anode as can be seen in

the picture below.

So I decided to manually

move the nickel anode slowly over the surface of the RF shield.

After about 40

minutes, I was happy with the result.

The finish isn’t perfect

but it looks ok and more importantly it will not rust!

So all I had to do now

was to reassemble the C16; starting with the keyboard.

The insulation which

covered the Shift Lock switch on the PCB had left a dried out glue residue on

the PCB so I gave that a clean with some IPA and a cotton bud.

Then I set about

refitting the Key Plungers and Shift Lock switch; the photo below shows the

location of the shift lock switch. It is a simple push fit and it clicks into

place.

The more eagle eyed

people out there will notice that I have fitted it with the solder pins facing

the wrong way; the pins should be pointing towards the middle of the housing

and not towards the outside of the housing… Something I would find out in a couple

of minutes!

After the shift lock

switch has been fitted, refit all the key plungers into the remaining sockets.

Note that they can only go in one way.

Once done, refit the

keyboard PCB.

This is where I

realised my mistake about the Shift Lock switch!

So I refitted it as

shown below.

Now refit the keyboard

PCB; securing it with the 23! Small cross headed screws.

Once refitted, it is

time to re-solder the two wires from the PCB to the Shift Lock switch. As I

simply melted the wires off earlier, I decided to clear the solder from the

wires using my de-soldering tool.

Then solder the 2

wires into position.

And finally insulate

the whole switch wiring with a piece of insulation tape.

Now refit the keys;

starting with the Spacebar as it is awkward if not impossible to fit it with

the next row of keys fitted behind it.

The easiest way to fit

this is to click the supporting bar into position as shown below.

Then remember to fit

the spring.

Slip the supporting

bar supports into the slots on the keyboard housing.

Then push down firmly

to secure the space bar into position.

The remainder of the

keys are relatively simple to fit; all you have to do is to fit the spring and

push fit the keys into the correct position.

However…

I made my second and

found my third error when fitting the Function keys!

Here I chose the wrong

plunger socket to fit the key on to the keyboard.

It looks ok until you

try to fit the lid (which I will show you later ;)

Then I tried to fit

the F2/F5 key and it took an agonising five minutes to figure out what was

wrong!

The plunger must have

moved out of position by 45° when I fitted the keyboard PCB! I only hoped that

I wouldn’t have to remove all the keys to fix this error.

To fix it, I removed

half of the small screws fixing the PCB to the housing.

The lever the PCB up

to allow access so that you can correctly seat the plunger in the correct

position.

Then fit the removes

PCB screws again.

After that, refit the

remaining Function keys.

I then noticed some

heat sink compound on my mat and on the keyboard PCB and found that there was

heatsink compound on the PCB wiring loom. This must have come from the heatsink

compound that I found on the TED Chip at the start of this series of

restorations.

I gave it a clean with

some IPA and a paper towel.

Now refit the keyboard

to the lid of the C16.

And it was here when I

found out about the function keys being fitted incorrectly.

So I removed the keys

then refitted them into the correct plunger socket on the key.

Now refit the 8 main

Keyboard fixing screws.

And then refit the

Power LED by pushing the LED into position until it clicks.

Then push on the

retaining ring to secure the LED into position.

With the lid complete,

I decided to refit the bottom half of the C16. Starting with the serial number

label.

For this I used some

wide double sided tape, a scalpel and a steel ruler.

Place the label on the

sticky side of the tape and smooth out the label with your fingers. As the

corners of the label were bent up originally, I paid particular attention to the

corners when sticking the label on to the tape.

Then carefully cut away the unwanted double sided tape with a scalpel and a steel ruler.

After that you should have a label looking like this; time to fit it on to the base of the C16.

Then peel off the

double sided tape backing and stick it into position; again I paid particular

attention to the folded corners ensuring that they were pushed down firmly on

to the base of the C16.

Now refit the main PCB

to the newly cleaned and rust free RF shield.

Remember to fit the

cardboard insulator on to the RF shield before fitting the motherboard.

The fit the

motherboard and secure it using the 6 small metal clips found on the RF shield around

the outside of the PCB.

Fit the bezel on

between the PCB and RF shield in the correct position so that the gaps line up

with the switches and sockets.

Then fit the 6 small

self-tapping screws into the positions shown below, followed by the 2 machine

type screws for the bezel also shown below.

Now refit the Power

LED connector from the lid of the C16 to the PCB; ensure that the red wire

points towards the middle of the PCB.

Then fit the keyboard

connector; this can only fit in one way round due to a blocked socket on the

connector.

Finally refit the

three main fixing screws.

Now give the Commodore a polish; for this I used some non silicone wood silk with bees wax polish. I have heard that WD40 works quite well but I didn’t want an oily finish or a C16 which smells of WD40 (no matter how good it smells)

I have also heard that

Armorall (Dashboard polish for cars) is quite good but it is a wee bit more

expensive than the £1.50 I paid for the furniture polish (have I told you that

I am an Aberdonian?)

For best results,

spray the polish on to a microfiber duster and not directly on to the C16. Then

polish the C16 ensuring that you manage to cover every nook and cranny of the

computer.

And you should have a

beautiful looking machine as shown in the picture below.

Now as I carried out a

rather intrusive deep clean which involved cleaning the motherboard with IPA as

well as a complete strip down of the keyboard, I wanted to test the system to

make sure it still worked, so I hooked everything up and loaded Saboteur.

Another success!

Well this part of the

restoration was quite eventful; I had a stinking cold which my apprentice geek

kindly gifted me; there was another eruption at Geek Mansion where I was called

some very bad names and I made three small errors when rebuilding the computer.

But it was a whole lot of fun and I got the chance to do some chemistry and try

out my 5A power supply for the first time at higher currents!

Below is my youTube

clip of the process from start to finish.

I hope that you have

found this entry useful; if you have any questions about the process, please

frel free to leave a comment or email me directly at

Thank you for taking

the time to read this long entry!

Next up I am going to

attempt to fit an internal SD2IEC unit into the computer without the need to

drill holes for the switches and LED’s.

- Get link

- X

- Other Apps

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

Comments

Post a Comment