Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

TI99/4a PAL Composite Video Mod for the PHA 2036 Modulator

This

modification only works on the PHA 2036 Modulator (the metal cased modulator)

There is a tutorial available on the TI-99 Italian User Club Website should you happen to have the plastic PHA 2030

modulator.

www.ti99iuc.it

Many thanks goes out to Sergio

Vigano and the TI-99 Italian User Club for making this modification public.

My TI99/4a had a reasonable picture

on my modern TV using the RF cable; it was quitter stable and the colours were

pretty good as well. But as I am planning to restore and upgrade the classic

computer I decided that I would try my hand at the composite video mod found in

the link above.

The website is excellent, it has

clear and easy to follow instructions and I did think about doing the

modification exactly as shown on the site. But then I decided to try and

improve the mod a little bit, so I ordered some parts from Amazon and eBay.

I have included screenshots of the

exact parts I ordered for this mod during the clip.

I wanted to try and keep the

modulator looking as close to the original as possible and decided that I would

order a 4 pole 3.5mm chassis mount socket and a 3.5mm to RCA cable so that I

could connect it to the TV using a standard SCART adapter.

I also decided to mount the socket

out of the same side of the modulator as the RF socket is on.

As far as modifications go, this one

was pretty easy but it does require some tooling which you may not have such as

a drill. There is another procedure for this mod available on the TI-99 Italian

User Club which requires less tooling.

Tools required:

Cutters

Pliers

Soldering Iron

Powered Drill (with stand if

possible)

Shifting Spanner

Tweezers

Heatgun

Tapered Reamer (only if you don’t have

an 8.5mm drill bit)

3mm HSS Drill Bit

8.5mm HSS Drill Bit

Flat Headed Screwdriver

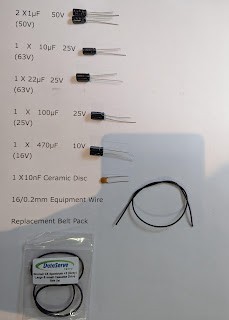

Components required:

4 pole 3.5mm chassis mount socket

4 pole 3.5mm jack plug to RCA

connectors cable (I would reccomend about 2M in length)

1.5mm Heatshrink Sleeving

3mm Heatshrink Sleeving (or cable

ties)

Around 300mm of the following

colours of 7/0.2mm equipment wire

Black

Yellow

White

I found the

4 pole 3.5mm chassis mount socket in Amazon; see picture below for the exact

one I ordered.

And the RCA

cable from eBay; I had bought a small 0.5M cable for another project so used

this smaller cable during the modification. I have since bought a longer 2M

cable which was actually cheaper than the 0.5M cable!

Before we

start this mod, you need to determine if the TI99/4a’s modulator is the correct

version for this type of mod.

Below is a

picture of the correct modulator.

Let’s have

a look inside the modulator and figure out the best place to fit the socket.

Remove the

two small case screws on the modulator with a small flat bladed screwdriver.

Below is a

picture of the inside of the modulator and my proposed location for the 4 pole

socket.

I chose

this location for a couple of reasons:

1

I

could have drilled the hole to the right side of the modulator as shown in the

tutorial in the TI-99 Italian User Club but upon inspection I found that

fitting the connector there would be difficult due to the length of the

connector.

2

I

wanted the cable to come out on the same side as the original RF cable.

3

I

wanted to drill the hole with the minimum chance of damaging any of the

components inside the modulator such as the variable capacitor highlighted

below.

So after

some careful measurements I found that if I drilled the hole 60mm from the left

of the modulator and 15mm from the top, this would ensure that I would have

little risk in damaging any of the components.

Measure and

mark the case with a permanent marker (use IPA to remove the ink afterwards)

Then punch

the location of the hole with a centre punch (if you have one) I didn’t have my

one to hand for this mod so I carefully scored the hole location with a

scalpel.

Measure the

connector to determine the correct hole size; the data sheet said that the

threaded end of the connector was M8 but I decided to measure for myself just

in case using my vernier callipers.

After

reading the callipers I decided that an 8.5mm hole would suit but as my drill

bit set only went up to 6.5mm, I would have to use a tapered reamer to enlarge

the hole further from the 6.5mm.

Then drill

the hole; I got to try out my new drill press stand for this (but if you are

careful use a standard powered drill or hand drill) I found that the best way

to hold the modulator in my vice was to refit the lid of the modulator.

As a 6.5mm

hole is quite large, it is best to drill a pilot hole; this would help avoid

any wobbling of the drill bit on the modulator. I opted to use a 3mm HSS drill

bit for this.

Fit the 3mm

drill bit to the drill and set the depth to drill the hole just below the metal

plate of the modulator; this would also reduce the chance of damaging any of

the components inside the modulator.

Drill the

pilot hole then enlarge it with either an 8.5mm drill bit or in my case a 6.5mm

drill bit. On a safety note, please wear safety glasses whilst doing this!

Once

drilled, I used a tapered reamer to gradually enlarge the hole; note that I

opened up the modulator again to ensure that the tapered reamer didn’t cause

any damage to the electronics.

Ideally,

the connector should be a tight fit but you do not want to have it too tight as

you will risk damaging the plastic thread on the connector.

Once the

socket fits snugly, remove any sharp edges caused by the drill with a file on

the inside of the modulator and if needed use a de-burring tool on the outside

of the modulator.

Now it is

easier to solder the wires on the socket before fitting it to the chassis of

the modulator but I wanted to double check the connections from the socket to

the RCA cable so I dug out my multimeter and did some continuity tests.

The photo

below shows the connections of the socket taken from the manufacturer’s data

sheet.

However, I

found that after testing, the actual pinout for the socket to RCA cable was as

shown below.

Below is my

wiring diagram for the socket; you will see that I have linked pins 1 and 2

together. Some modern TV’s will automatically put sound to both speakers when

it only has a mono input but in case either of my Geek TV’s didn’t I decided to

link pins 1 and 2 together which should ensure that both speakers get the same

audio from the mono feed from the TI99.

For wiring

up the socket to the modulator I used three 300mm lengths of 7/0.2mm equipment

wire. For the Video Pin, I decided to use Yellow, for the GND, I used Black and

for the Audio, I decided to use white instead or Red as I usually only use red

for a positive DC Voltage wiring.

Now with

the socket in the helping hands, strip twist and tin 5mm of insulation from the

Black and Yellow wires.

As we are

going to link pins 1 and 2 together, strip twist and tin about 10mm of insulation

from the white wire.

Now place

the stripped black wire through the small hole on Pin 4 of the socket and

solder it; I find the easiest way to keep the wire in place is to use a pair of

cutters or pliers to put tension on the wire as shown below.

Then repeat

the process for the Yellow wire on Pin 3 of the socket.

Now make an

‘L’ shape with the white wire with the tinned part bent over at a right angle

from the insulation. Solder the tinned part on to Pin 2 and bend the excess

tinned wire over to pin 1 and solder it.

Trim the

excess tinned wires away from the socket.

Cut 2 15mm

lengths of 1.5mm heatshrink sleeving and fit over the Yellow and black wires;

ensure that no exposed conductors are showing then shrink the sleeving with a

heatgun.

And you

should have a socket with the wires coming from the pins looking like this.

Now fit the

socket to the chassis of the modulator; I used a shifting spanner to tighten

the nut which reduces the risk of scratching the black paint on the chassis.

Now cut 4

10mm lengths of heatshrink sleeving; I prefer to use heatshrink sleeving in

place of cable ties to group the wires as I think that it looks neater.

Then route

the wires as shown below, fit the sleeving and shrink it down with a heatgun.

Now solder

the Black, Yellow and white wires on to the following positions as shown in the

picture below.

It is a good idea to tin each position before soldering the wires on to them; this is quite fiddly for pins 3 and 4 of the modulator due to its close proximity to the chassis.

Strip,

twist and tin 5mm insulation from the Black wire.

Then solder

the black wire on to position 3 on the modulator.

Fitting the

Yellow wire to Pin 4 is exactly the same process, cut the wire to length,

strip, twist and tin 5mm insulation and solder it on to position 4.

I found it

easier to use tweezers to hold the wire in place when soldering the yellow

wire.

Now cut the

White wire to length, strip twist and tin 5mm insulation and solder it on to

the lower leg of the 330Ω resistor as shown in the earlier

wiring diagram.

And you

should have a modulator looking like this.

Reassemble

the Modulator.

Then hook

up your TI99 to a SCART adapter on your TV or monitor.

And test!

This works perfectly! Again, many

thanks to Sergio Vigano and the TI-99 Italian User Club for making this

modification public.

Below is my youTube clip of the

whole process from start to finish.

I hope that you have found this

useful.

If you have any questions or queries

about this mod then please feel free to leave a comment or email me directly at

alleged_geek@aol.com

Thank you for taking the time to

read this entry, the next in my TI99/4a series is a complete Re-Cap of both the

Motherboard and Power Supply PCB’s

- Get link

- X

- Other Apps

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

Comments

Post a Comment