Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

In this entry I am demonstrating how to overhaul the

Cassette Drive on the ZX Spectrum +2 (grey) computer.

Before we start, I would like to apologise for the

picture quality on some of the images; I was trying out a new video camera for

the first time and the quality at best is average!

I had initially intended to do a simple recap of the

drive as the capacitors are at least 36 years old!

I stumbled across this great link whilst researching

what I should be looking for.

Servicing

your +2's Datacorder - Spectrum for Everyone

It also had loads of information about other

modifications I could do to the drive.

In this entry, I will show how to

Recap the PCB

Change the drive belts

Clean the tape heads

Modify the PCB to include external components found on

later models of the +2

And prevent the grounding problem that can occur when

the screws holding the PCB to the chassis of the drive become corroded.

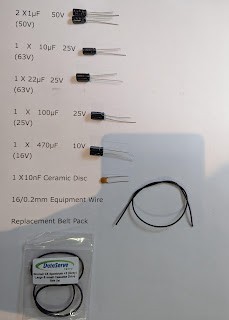

For this mod you will need the following components

1 X 1µF 50V electrolytic capacitors

1 X 10µF 25V electrolytic capacitor

1 X 22µF 25V electrolytic capacitor

1 X 100µF 25V electrolytic capacitor

1 X 470µF 10V electrolytic capacitor

1 X 10nF ceramic disc capacitor

Small piece of equipment wire

Replacement belt pack

Tools required are

Soldering Iron

De-Soldering tool

Cutters

Pliers

Screwdriver

Miscellaneous Items (which were helpful but not

necessary)

Scalpel

Isopropyl Alcohol

Toothbrush

Cotton buds

Air Duster

A YouTube clip of this mod from start to finish can be

found at the end of this entry and on my YouTube channel.

If you have any questions about this mod, please feel

free to leave a comment or email me directly at

alleged_geek@aol.com

Any feedback, good or bad would be greatly appreciated.

So, let’s get started!

Pictured below is the original tape loading test with

my original copy of Horace and the Spiders

The tape loaded without any issues so I knew that the

tape drive was working but as I said previously, I originally wanted to do a

simple recap of the PCB.

Before I could start that I had to disassemble the +2

Then I had to remove my TZX Duino modification

Removal of the TZX Duino modification was simple; all I

had to do was to melt the solder on the following vias then gently pull the

wires from the PCB. Care should be taken not to burn your fingers whilst doing

this.

First up was the yellow wire

Then the red wire

Next was the black wire

And to remove the white wire, all I had to do was to

push the yellow button to release it from the PCB connector

To remove the cassette drive from the +2, there are 5 fixing screws shown below.

The 5th screw is difficult to get to despite

there being a hole on the PCB for access so I decided to remove the drive PCB

for better access to the screw.

The location of the screws can be found in the picture below.

Remove the first screw

Then the second screw

And note that the third screw in position 3 is a lot

longer than the other 2 screws.

Now we have access to all 5 of the cassette drive fixing screws.

The 5th screw is still a little awkward but

at least with the PCB out of the way it is easier to get hold of when loosened.

The cassette drive is not completely free at this point as the power LED PCB is attached to the drive so remove the fixing screw shown in the picture below.

Below is a picture of the removed cassette drive

I then tested the tension on the belts and found that

the long belt was pretty loose around the pulleys. This is understandable as

they are over 36 years old now and the rubber was beginning to perish slightly

Now let’s have a look at the PCB and capacitor

locations and orientation.

First up is C318; it is a 10µF 50V Electrolytic

Capacitor.

The picture below shows its location and orientation on

the PCB.

The next capacitor is C324 which is a 22µF 25V

Electrolytic Capacitor.

It’s location and orientation can be found below.

The 3rd capacitor to replace is C315 which

is a 100µF 25V Electrolytic Capacitor and again it’s location and orientation

can be found below

The final capacitor to replace is C322 which is a 470µF

10V Electrolytic Capacitor, it’s location and orientation can be found below.

To remove the capacitors you will need either a

de-soldering tool, solder wick or in my case (a new tool) an electric

de-soldering gun!

Let’s start with C318, the 10µF

Below is a picture of the vias on the solder side of

the PCB to remove the solder from.

Once located, de-solder the capacitor

When using my new tool, I placed the gun over the

solder joint then added some fresh solder before pulling the trigger. This

makes the de-soldering process a whole lot easier.

I would also recommend adding fresh solder to the joint

before using a de-soldering pump or solder wick.

Take care when removing the capacitor from the PCB as

you can cause damage to the PCB if any solder is left in the via. Before you

remove the capacitor, you may want to pick at the de-soldered legs of the

capacitor to see if they are free.

Also, it is a good idea to watch for any physical resistance when pulling the capacitor out. If there is any resistance, simply try the de-soldering process again.

When doing a recap on any PCB I find it best to remove

and replace the capacitors one at a time. This should ensure that you don’t get

the values mixed up and it is also easier to remember the orientation of the

capacitor.

The new 10µF capacitor is shown below and I have

highlighted the negative leg with a pair of tweezers.

Place the new 10µF in the PCB below is a picture to

remind you of its orientation.

Turn the PCB so that you can see the solder side then

hold the capacitor flat against the component side of the PCB and gently bend

the legs of the capacitor out to 45° (this will ensure that the capacitor will

remain flat against the component side when soldering)

Then solder.

Once soldered, trim the legs of the capacitor with your

cutters.

The next capacitor we are going to replace is C324 which is the 22µF, below is a picture of its location and orientation again.

The location of the vias are shown below.

De-solder the capacitor as before and refit in the

correct orientation. This one is easier to describe as the negative side of the

capacitor faces outwards from the PCB as shown in the picture below.

C315 the 100µF capacitor is next, location and

orientation shown below.

The vias can be found highlighted in the picture below.

And again, refitting in the correct orientation is made

easier because the negative side of the capacitor faces outwards from the PCB.

The last capacitor to replace is C322 which is the

largest capacitor in value and size; it is a 470µF 10V electrolytic capacitor.

The voltage ratings of the capacitors are very

important as using a lower rated capacitor will cause the component to fail and

probably damage the circuit. In this case I used a 16V rated capacitor as it

was all I had in stock at home.

Below is a picture of its location and orientation.

The vias can be found highlighted in the picture below.

Once all the capacitors have been replaced, it is time

to clean the cassette drive. After 36 years, there was quite a collection of

dust and fluff within the workings of the drive. Use a soft brush to clear away

the larger collections of fluff and dust.

Then I used an air duster can to loosen the stubborn

fluff and dust before going over the drive again with the soft brush.

After most of the grime had been removed I used some

IPA and a cotton bud to clean all the metalwork on the drive. Take care not to

get any IPA on the gears or bushes as this will dissolve the grease and will

cause problems in the future.

Next clean the pinch roller pictured below with some

IPA and a cotton bud. This pinch roller was particularly dirty as you will see

in the video.

After the pinch roller is clean, use a new cotton bud

and some IPA to clean the tape heads. Take care doing this as you do not want

to damage the tape heads by being too rough with the cotton bud.

Now it is time to replace the tape belts.

I bought this replacement belt pack from Dataserve for a couple of pounds.

Removing the large belt is easy; you simply just pull

it off.

The smaller belt was very fiddly to remove as you have to slip the belt in between the pulley and the plastic spring loaded cap. Care should be taken when doing this as it is very easy to damage the spring loaded cap.

Refitting the smaller belt was even harder than

removing it! I ended up using a scalpel to gently push down on the spring

loaded cap until I was able to slip the belt in-between the cap and the pulley.

Take care when using a scalpel as they are incredibly

sharp; it is easy to damage the belt or even worse cut yourself with the blade!

Once fitted, you will find that the belt is probably twisted or kinked, to seat the belt correctly in the pulleys simply spin the pulleys and the belt will slip into the correct position.

Refitting the large belt is easy, use the same

technique to seat the belt in the pulleys correctly.

The next part of the mod is to reduce the noise due to

poor grounding which is often found on the issue 3 +2 ZX Spectrum.

Some later versions of the issue 3 +2 ZX Spectrum also

had a 10nF ceramic disc capacitor and a 1µF electrolytic capacitor soldered

into the circuit which also reduced the noise produced on the output.

Although I couldn’t hear any humming or noise on the

audio output, I decided to do this mod anyway as it wouldn’t harm the circuit

even if it wasn’t required.

First up, lets fit the 10nF ceramic disc capacitor.

Below is a picture of the location of the vias where we are going to solder the

capacitor.

First we will prepare the capacitor by trimming and

tinning the legs (add solder to the legs of the capacitor)

Next, add fresh solder to the highlighted vias shown earlier as this will make soldering a bit easier.

Then solder the capacitor in the position shown below.

Next we are going to solder the 1µF capacitor on to the

vias shown in the picture below.

Bend the legs of the capacitor so that it will sit flat

on the PCB after soldering.

As before, tin the legs of the capacitor and add fresh

solder to the above vias.

Ensure that the orientation of the capacitor is correct before soldering, then solder; you should have something looking like this after you have finished.

After that, we are going to solder a wire link from the

GND located at the centre of the PCB to another GND point on the PCB. This is a

simple mod to ensure that the PCB is grounded at all the GND points on the

board.

Pictured below is the location of the vias we need to

solder the wire link.

Use either your cutters or wire strippers (if you have

a pair) to strip 5mm of insulation from the wire. Twist the strands together

and tin the end (cover it with solder)

Then cut the wire to length and repeat the above with

the other end of the wire.

After the wire has been tinned on both ends solder it on to the vias shown above and you should have something looking like this afterwards.

After all the new soldering it is a good idea to clean

the PCB with some IPA alcohol. I used Mrs Geek’s new toothbrush (which was her

Christmas gift from me) to scrub away the old and new flux residue on the PCB.

Using a toothbrush is a good way to get the stubborn

fluxes removed but it will leave the PCB coated in a sticky fluxy residue.

To clean the PCB properly after scrubbing, I used some more IPA and cotton buds.

That is now the overhaul completed, it is now time to

reassemble the +2.

Starting with fitting the cassette drive.

Before fixing the drive to the case of the +2, remember

to fit the power LED PCB as fitting this after the tape drive has been fitted

is awkward.

Fitting the drive is pretty easy and is a reversal of

removing the drive. I did fit the three visible fixing screws before removing

the PCB and fitting the hidden screw.

After fitting the awkward ‘hidden’ screw, reattach the PCB using the 3 screws shown below.

One thing to note is that the final PCB fixing screw is

longer than the other two as well as being self tapping.

Once the PCB has been secured fit the final drive screw

next to the motor and that should be the cassette drive fitted to the case of

the +2.

Now I am going to reattach my TZX Duino tape loading

modification. Again it is relatively straightforward and a reversal of the

removal.

Solder the Yellow, Red and Black wires into the

positions shown below then reconnect the White wire to the PCB connector.

Finally, reassemble the +2

All we have to do now is test the system which you can

see and hear on my Youtube clip at the end of this post.

Below are a couple of pictures showing that Horace and

the Spider loaded successfully!

Below is a video clip of the modification from start to finish; apologies again for the poor video quality!

In fairness, I didn’t hear any audible difference when comparing the pre and post mod tape loading but the overhaul was just an added bonus as I had the tape drive apart to do the Re-Capping.

The tape belts were a bit loose so it was good to replace those before they became a problem.

I hope that you have found this entry informative, if

you have any questions about this mod or need any advice then please feel free

to leave a comment or email me directly at

alleged_geek@aol.com

Thank you again for taking the time to read the long

entry!

- Get link

- X

- Other Apps

Comments

Post a Comment