Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

Make your Own Joystick Adapter for the Commodore C16

Make your own

Joystick Adapter for the Commodore C16 to allow play with a standard Atari type

joystick.

In this entry I

am demonstrating how to make your own Joystick Adapter for the C16. I have

shown two methods; one is far easier than the other!

In the first

method, I bought an 8 pin Mini Din Male to male cable and simply soldered a 9

pin D-Type Male connector to the other end. I did of course have to buzz out

the wiring to individual pins but it was pretty straightforward.

The second

method, I actually bought an 8 pin Male Mini Din connector and soldered the

wires directly on to it. This was extremely fiddly; my patience was tested as

well as my eyesight!

I finished up by

testing both joystick ports using different games.

Tools Required:

Cutters

Pliers

Soldering Iron

Helping Hands

Multimeter

And a whole lot

of patience!

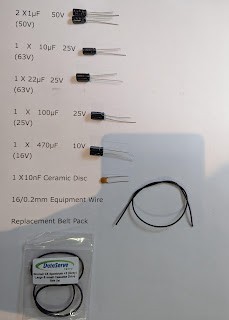

Components

Required:

Solder

1.5mm Heatshrink

Sleeving

8 pin Male Mini

Din connector

9 pin Male D-Type

connector with solder buckets for ease with soldering

8 Pin Male to

Male Mini Din Cable

For the first

method, I bought an 8 Pin Male to Male Mini Din Cable from eBay.

As well as a 9

Pin Male D-Type connector with solder buckets and shell housing; again from

eBay.

Cut the cable in half then strip around 40mm of the outer

insulation from the end of the cable.

Then strip and twist about 5mm insulation from each wire.

I used a female Dupont cable and fitted it on to the pins of

the Din plug.

Below is a picture of the pin configuration looking directly

into the Din plug.

Now use a multimeter to find out which wire goes to which

pin on the cable.

Buzzing out the cable I noted down the colours of wires and

the pins they were connected to.

Pin Colour Function

Pin 1 Red UP

Pin 2 Pink DOWN

Pin 3 Green LEFT

Pin 4 Yellow RIGHT

Pin 5 Orange +5V *not really required

Pin 6 Black FIRE

Pin 7 Purple GND

Pin 8 Not required SELECT

Here is my wiring diagram for this method; all wires are

colour coded and both pin views are taken from the solder side of the two

connectors.

Now prepare the wires for soldering on to the D-Type plug.

Strip, twist and tin about 5mm of each wire.

Then cut seven 15mm strips of 1.5mm heatshrink sleeving.

Now prepare the 9 pin Male D-Type Connector for soldering.

To make things easier, I bought a 9 Pin Male T-type

connector with solder buckets. From experience, I find that it is best to add

some solder to the solder buckets then simply melt the solder in the relevant

pin and slide the tinned wire into the solder bucket.

Again, making things easier, only add solder to the pins

required; in this case I added solder to pins

1, 2, 3, 4, 6, 7 and 8

Then slip the heatshrink sleeving over the first wire and

solder it on to the correct pin.

In this case I started with the Red wire and soldered it on

to Pin 1 of the 9 pin D-Type plug.

Then Slip the Heatshrink sleeving over the pin.

Repeat the process for Pin 2 – Pin 4

Pin 2 is the Pink wire

Pin 3 is the Green wire

Pin 4 is the Yellow wire

Turn the D-Type connector round in the helping hands then

repeat the process for Pins 6 – 8.

Pin 6 uses the Black wire

Pin 7 is the Orange wire

Pin 8 is the Purple wire.

You should note that the numbering on the pin outs almost

matches pin for pin. The only exception is the GND pin which is on pin 7 of the

Mini Din plug but is on Pin 8 of the D-Type plug.

With all the wires soldered in place, ensure that the heatshrink

sleeving is covering all exposed metal or wires on the pins then use a heatgun

to shrink them in place.

Now fit the D-Type cover.

Fit the cable clamp over the outer insulation of the cable

(about 5mm from the end of the insulation)

Then gently twist the connector round a turn; this keeps the

wires together nicely when fitting the connector to the shell.

Fit the wire and cable into the shell; the cable clamp fits

into the space at the top of the shell (where the wire sticks out)

Then screw the D-Type cover together using the long screws

and nuts.

And that is it; the first adapter cable made!

Now for the awkward method…

Using an actual 8 Pin Male Mini Din Plug!

I bought the following Mini Din Plug from eBay.

As you can see from the picture below, the pins are spaced

very close to one another!

This is going to be fiddly!

Below is a picture of the tools and equipment used for this job; although I did switch to using my helping hands to solder the wires on to the mini din plug.

The wiring diagram for this method is shown below; upon

reflection I should have really used the same colours for the wiring as I did

for the first method. My only real reason for changing the colours is that I

wanted to use the Black wire for the GND function.

Now prepare the wires and connector for soldering.

Strip 40mm outer insulation from the 8 core cable.

Then cut six 10mm strips of 1.5mm heatshrink sleeving.

Strip 5mm insulation from the six wires used.

Then tin the wires.

Place the Din plug in the vice; below is a blurry picture of

the Din Plug in the vice. Note that I have it held in place as shown in the

diagram with pin 2 on the bottom left hand side.

Now tin Pin 2.

Fit heatshrink sleeving over the Yellow wire then solder it

on to Pin 2 of the mini Din plug.

Slide the sleeving over the pin; ensure that no exposed

metal is showing. And then shrink the sleeving using a heatgun.

I opted to shrink the sleeving on the pins as I soldered each

pin in turn which reduces the risk of short circuiting the other pins when

soldering.

Repeat the process for the Blue wire which is to be soldered on to Pin 1 (to the right of Pin 2 as you look at the solder side of the Din Plug)

The first real issue happened at this point; I melted the

plastic pin holder! I think it was a combination of my soldering iron being a

wee bit too hot and possibly a little bit too much heat from the heatgun as I

shrank down the sleeving on Pin 2.

Never the less, it was a fiddly job to reheat the pin and

push it back into place! I ended up removing the soldered wire, then reheating

the pin with my soldering iron whist pushing it down on to a flat surface until

the pin was the same height as the other pins.

Then I fitted heatshrink sleeving over the blue wire and

re-soldered it on to Pin 1

You will notice that I turned the temperature down from 330°C

to 300°C

for the remainder of the soldering.

That was only the start of my troubles!

I opted to solder Pin 4 next (the Pink wire) this proved to

be very testing… both my patience and eyesight were strained to the limit! My

52 year old eyes are not as good as they used to be even with glasses on!

The main issue was that Pin 4 was in the middle of the

connector and all the other pins are extremely close to it. Care has to be

taken when tinning and soldering on to this pin as it is very easy to short out

other pins with excess solder. The other issue is that the pins themselves are

easily snapped off if they get bent out of position.

No matter how I tried to tin Pin 4 using my vice to hold the

connector; I couldn’t get the right angle for my soldering iron to heat the pin

and add solder to it. I tried in a few different positions and even tried to

solder it whilst holding the connector in my hand. This was very frustrating!

Finally I gave up! And decided to take the risk and use my

helping hands!

This proved to be slightly less awkward and I had the advantage

of the magnifier glass… finally I could see perfectly again! As well as getting

a better position for my soldering iron.

What should have taken a few seconds to solder ended up

taking over 5 minutes but I got there in the end! The pink wire was finally

soldered into place!

Pin 3 was next (the Green wire) and as it was an outside pin

it was relatively straightforward! I soon had it soldered into position and

heatshrunk.

The next pin (pin 7) I soldered was again a wee bit fiddly

due to the close proximity of the other pins but as it was an outside pin I did

manage to get pretty good access with my soldering iron.

I fitted heatshrink sleeving over the Black wire and

soldered it on to pin 7 (the middle pin on the top row of pins.

The last pin (pin 6 the Purple wire) was relatively pain free and I soon had it soldered into position.

I then inspected the connector; looking for any short circuits

and when happy I fitted the Din Plug housing over the connector. For those with

a keen eye, you will notice that I forgot to fit the final outer housing over

the connector! I had to go back and do that later!

Now it was just the case of soldering the six wires to the 9

Pin D-Type plug and this was done exatly as before.

Strip 40mm of outer insulation from the other end of the

cable and cut off the unwanted wires.

Add solder to the solder buckets in positions 1, 2, 3, 4 , 6

and 8 of the D-Type Connector.

Cut 6 15mm strips of 1,5mm Heatshrink sleeving.

Strip, twist and tin 5mm insulation from each wire.

Then solder each wire as per the diagram below; remember to

fit the Heatshrink sleeving before soldering.

I started with the Pink wire and soldered it on to Pin 4

Then I soldered the Green wire on to Pin 3.

The Yellow wire on to Pin 2

And the Blue wire on to Pin 1

Then I turned the D-Type connector round so that pins 6 – 9 were

facing upwards.

Then I soldered the Black wire to Pin 8

And the Purple wire to Pin 6

Use a heatgun to shrink the sleeving in place; ensure that

no expesed metal is showing before shrinking the sleeving.

Then fit the D-Type housing as before.

Now it is time to test the cables!

The Commodore C16 has a strange joystick setup, some games

only work with port 1 and some only work with port 2. If you end up using the

wrong port, some of the functions on the joystick do not work correctly. I

demonstrated this when testing out the joystick adapters whilst playing Manic

Miner.

I used the correct port first and as you will see the

joystick functions perfectly.

Set up the Commodore C16 with both joystick adapters fitted

and using standard Atari type joysticks. The original Atari stick is one of my

personal favourites due to the Atari VCS (2600) being my first ever console so

I connected my original Atari Joysticks to the Adapters.

I loaded Manic Miner and tried the first joystick as shown below and it worked flawlessly!

However, when I tried the second port, I found that Miner

Willy moved to the left when pressing the fire button!

If I didn’t know about the issues with the joystick ports of

the C16 mentioned earlier, I would have put it down to faulty soldering on the

connectors.

But, to be on the safe side I decided to load up a game

which works with both ports; in this case it was Invaders.

Here I am playing Invaders with the joystick which didn’t work

with Manic Miner; thankfully everything worked as expected!

And I tried it out with the first joystick just for good

measure. Again, thankfully everything worked as expected!

Job done!

Below is a clip of the process from start to finish.

Well this is the last entry and clip in my Commodore C16

Repair, Restoration and Modification series and I am a wee bit sad about that

as I have had so much fun working on this beautiful under rated machine.

There have been tears, tantrums and jubilation as I took

this machine cleaned it up, modified it, killed it and brought it back to life

again. And I loved every second of it!

Now all that remains to be said is what I am planning to

work on next…

And after careful consideration, I have decided to work on

my TI99/4a

Again this is not a machine I was familiar with back in the

day and I am so much looking forward to finding out more about this peculiar

little machine.

Thank you for taking the time to read this entry, I hope

that you have found it useful.

If you have any questions about this entry or any of my

other entries then please feel free to leave a comment or email me directly at

alleged_geek@aol.com

Thank you again!

- Get link

- X

- Other Apps

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

Comments

Post a Comment