Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

Complete Re-Cap of a TI99/4a

In this entry I am doing a

complete re-cap of the TI99/4a. I managed to purchase direct replacement

capacitors which were mainly axial with the exception of one 470µF

radial capacitor.

This clip features a disassembly

of the TI99/4a followed by replacing all the capacitors with pictures of

locations and vias to de-solder.

Equipment required:

Cutters

Pliers

Soldering Iron

Tweezers

Prying tool

De-Soldering Gun or Solder Sucker

Solder Wick

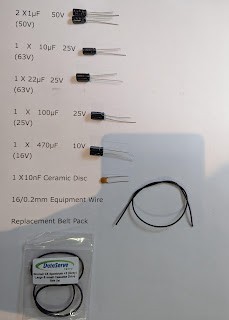

Components required:

Power Supply Board Electrolytic

Capacitors

2 X 47µF 16V Axial

1 X 1000µF 25V Axial

1 X 3300µF 35V Axial

1 X 4.7µF 50V Axial

1 X 470µF 12V Radial

Motherboard Electrolytic

Capacitors

You will also require some

Heatsink Compound

And some IPA

I have included an embedded YouTube clip of

the whole process at the end of this entry.

Before we can replace the

capacitors we must get inside the computer; this was my first attempt at it so

I will include the stripdown as part of this entry.

Remove the switch slider from the

front of the TI994a; It came out easily with the use of a prying tool.

After that, remove the 7 case

screws with a small cross headed screwdriver; the ones highlighted in Yellow

were smaller in length than the ones highlighted in Green.

Then remove the 2 fixing screws

for the Power Supply PCB.

The external power connector

simply lifts free from the case.

Now disconnect the connector with

the 4 brown wires which take the required voltage to the Motherboard +5 -5 +12

and 0V

Then remove the PSU PCB

Now it is time to remove the

motherboard; remove the three highlighted screws. It took me some time to

realise that the one in the middle had to be removed as well!

Lift the motherboard to about 90°

from the case.

And carefully remove the keyboard

connector from the motherboard; I gently wiggled it from side to side until it

slid off the pins on the motherboard.

Now remove the sideways edge

connector PCB.

Then slide off the two metal clips

from the sides of the RF shield.

Next, remove the three nuts blots

and washers which fix the RF shield to the motherboard.

The above locations have longer

screws than the picture shown below.

Now remove the RF shield.

Finally we can start to Re-Cap the

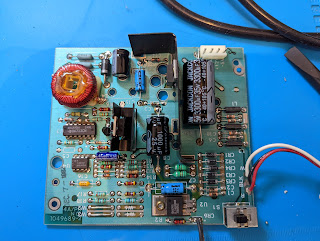

PCB’s; I started with the PSU PCB first.

Before we do so, I would like to

show you how to identify and read the markings on electrolytic capacitors.

Failure to solder them in the correct orientation can and will result in either

damaging the capacitor as they are prone to exploding as well as damaging the

circuit and PCB (see my YouTube clip for a demonstration)

Below are the typical markings and orientation

found on most axial capacitors.

And the picture below features the

typical negative side markings found on most radial capacitors.

It is very important to replace

the capacitors in exactly the same orientation!

I decided to replace the

Capacitors on the PSU PCB in their numerical order and below is a photo of all

the capacitors required for the PSU.

I did have most of them in stock

but I had to pay about £5 for the 3300µF 35V smoothing capacitor… it really

is a beast of a capacitor.

To make life easier it is a good

idea to replace the capacitors one at a time. Starting with C7; the picture

below shows the location of the capacitor on the component side of the PCB. I

have also marked the orientation of the capacitor but the silkscreen printing

on the PCB also marks the positive side of the capacitor.

We also need to know which vias to

de-solder in order to remove the capacitor so I have marked their locations in

the picture below.

With the information shown above,

de-solder the two highlighted vias; I used my de-soldering gun for this but a

simple cheap and cheerful solder sucker will work just as well.

I find it easier to de-solder after freshening up the solder on the vias; this is done by melting the original solder on the via and adding some new solder.

Take care when de-soldering as it

is very easy to damage traces on the PCB during the process. A wee tip when

using a de-soldering gun is to place it over the component leg, let the solder

melt (typically 2-3 seconds) give the nozzle of the de-soldering gun a ‘wiggle’

whilst pulling the trigger and removing the solder.

When I attempted to pull the

capacitor out from the PCB I felt some

physical resistance. This meant that not all of the solder had been removed

when using the de-soldering gun. Forcing the capacitor out at this stage would

damage the traces on the PCB so I resorted to a tried and tested technique.

Simply heat the leg and via of the capacitor on the component side until the

solder melts and gently pull the leg free from the PCB.

Once the capacitor has been

removed, it is a good idea to inspect the vias for damage or any signs old

solder which will prevent you from placing the new capacitor into position. I

found that there was a slight blockage on one of the vias so I used solder wick

to draw the solder up from the via.

Solder wick is relatively easy to

use but if used carelessly can result in damaging the traces. I find the best

way to use it is to place it flat over the via in question and simply lay the

tip of the soldering iron on top of the solder wick and as close to the via as

possible. Try and avoid trailing the soldering iron across the solder wick as

this can sometimes lift the traces underneath.

Most of the original capacitors on

this PCB had their information and orientation markings hidden from view. It is

a good idea to bend the legs of the new 47µF 16V capacitor into shape

using a pair of pliers and in such a way that the markings can easily be read

when looking down on the component side of the PCB after fitting.

And fit the new capacitor in the

same orientation as the original.

Below is a picture of the

orientation of C7

Once fitted, simply solder the

capacitor and trim the excess legs of the capacitor using a pair of cutters.

When trimming the legs, try and avoid cutting into the solder joint as this

will weaken the solder joint. I tend to trim just above where the solder stops.

Now we repeat the process for the remaining

five capacitors.

Starting with C8, 1000µF

25V

Here is the position and

orientation of C8 from the component side.

And below are the positions of the

vias to de-solder.

De-solder and refit the new 1000µF

capacitor in the correct orientation as shown above.

Then replace C9, the 3300µF

35V capacitor; to remove this you will have to remove the cable tie which holds

it into position on the PCB. Use a pair of cutters to snip the cable tie and

then remove it.

Below is a picture of the position

and orientation of C9 taken from the component side of the PCB.

And the picture below shows the

positions of the vias to de-solder on the solder side of the PCB.

De-solder and fit the new 3300µF

capacitor in the correct orientation.

The next capacitor to

replace is C10, 47µF 16V.

Below are the pictures of the

orientation and locations of the capacitor and its vias.

After replacing C10, replace C12

which is a 4.7µF 16V capacitor.

The pictures below show the

orientation and locations of the capacitor and its vias.

We now come to C15, 470µF

50V.This is the only radial capacitor to replace; however you could replace it

with an axial capacitor if you de-solder the via circled in black on the

picture showing the location of the vias

on the solder side of the PCB.

You will also have to remove the

cable tie which secures it to the PCB.

After replacing the final

capacitor you should have a PCB looking like this.

All that needs to be done now is

to fit a cable tie around C9. You could also clean the PCB with some IPA to

remove any flux residue and dirt. As I am planning a deep clean of the system I

will do this at a later point.

Now we come to the motherboard;

unlike the PSU PCB, the motherboard silkscreen does not have information about

the orientation or numbers of the capacitors.

So I started out replacing the

cluster of five capacitors in the area shown below.

Below is a close up of the area in

question.

I started with the 100µF

16V capacitor shown below.

Then after replacing that one I

moved on to the capacitor directly below it which was another 100µF

16V

The next capacitor I replaced was

the 10µF

50V shown below.

Then I replaced the 22µF

16V capacitor found in the position below.

The last capacitor in this cluster

was another 22µF 16V and can be found here

The next capacitor I replaced was

another 22µF

16V and can be found in the area shown below.

Here is a close up of the

orientation and location of the capacitor and its vias.

The next capacitor is a 100µF

16V and can be found in about the middle of the PCB.

Here I have highlighted the orientation

and location of the capacitor and its vias.

The next capacitor to replace is a

22µF

16V and can be found to the right of the previous capacitor.

The final capacitor to replace is

another 22µF

16V and can be found in the highlighted area shown below.

Here is a close up of the

position, orientation and location of the vias for the final capacitor.

After replacing the capacitors you

should have a PCB looking like this.

Now it is time to reassemble the

TI99/4a!

The first thing we need to do is

to remove the old dried out heatsink compound found on the V.D.C. Chip

(TMS9918A) with some IPA and a cotton bud.

Then remember to clean the old

heatsink compound from the metal heatsink found on the RF shield.

Apply fresh heatsink compound to

the V.D.C. chip; do not use too much heatsink compound for this. I recommend only

using a single even stripe of heatsink compound down the middle of the chip as

shown below.

Then refit the RF shield.

Screw the RF shield together using

the three nuts, bolts and washers.

I started with the smaller one

first.

Then fitted the two longer screws.

After that, refit the right angled

edge connector in the position shown below.

Then refit the two metal clips to

the sides of the RF shield as shown below.

Now refit the keyboard connector.

Then secure the motherboard to the

case of the TI99/4a using the three screws shown below.

Now refit the PSU PCB starting

with the power connector (this will only fit in one way)

Then secure the PCB to the case

using the two screws in the positions shown below.

Refit the main power socket

towards the rear of the TI99/4a; note that this simply drops into position.

Then refit the seven case screws;

note that the four screws towards the front of the case are shorter in length

than the three at the rear.

Finally, refit the power switch

slider; this simply pushes on.

Now it was time to test!

Set up the TI99/4a.

Switch on…

And…

Success!

If any of the capacitors have been

fitted in the wrong orientation it may take some time for them to fail so I

would recommend leaving the system on for at least 20 minutes which should be

long enough for any incorrectly fitted capacitors to fail.

Below is a clip of this

modification from start to finish.

I hope that you have found this

entry useful, if you have any questions or queries then please feel free to

leave a comment or email me directly at

alleged_geek@aol.com

Thank you for taking the time to

read this entry.

Next up in my TI99/4a series is a

FlashRom99 installation as well as a joystick adapter PCB.

- Get link

- X

- Other Apps

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

Comments

Post a Comment