Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

‘External’ Internal SD2IEC Drive installation

And Killing my C16 in the Process!

Hello and apologies for the delay bringing you this content; there are a couple of reasons but mostly due to a stubborn chest infection which lasted over a month! The other reasons you will find out during this entry.

For this entry, I would like to describe my idea behind this mod. I have seen external SD2IEC drives out there on eBay and other sites and they are reasonably priced but I decided that I would like something slightly different.

I stumbled across a blog entry where someone had installed his internal SD2IEC drive inside his C16 but although it works flawlessly, I would like to have access to the SD Card Slot as well as having status LED’s and the reset function button.

After a bit more research I found that someone had done just that but at the cost of having to modify the case of his C16. Although it did look good, I try and avoid destructively damaging any of my computers or consoles wherever possible… I like to have the choice of returning everything to its stock appearance.

So after a bit of measuring, I decided that I could fit a 3D printed SD2IEC holder in the cartridge slot at the rear of the C16.

As there are a few different Internal SD2IEC drives out there, I found one on eBay which appeared to be the smallest in size, so I spent the £30 and ordered it.

The above photo is of the one I purchased from eBay with the seller’s identity hidden.

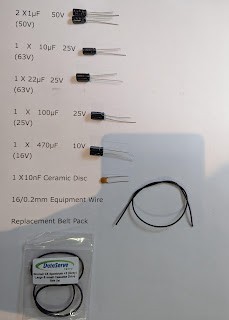

When working on any of my computers or consoles, I buy everything I plan to do to it at the very beginning then work out the order I am going to modify the system. In the C16’s case, I bought the capacitors required for the re-cap, the memory upgrade IC’s, heatsinks, the SD2IEC drive as well as a JiffyDos kernel rom which I am planning to install next. I have also bought connectors for a joystick converter which I am also planning to write about.

The downside of this is that I have the parts sitting in stock waiting to be installed and this was my downfall regarding the SD2IEC drive. By the time I got round to installing it, I found that it was faulty… no problem, all I had to do was write to the eBay seller and ask for advice to see if there was anything I needed to do to get it working such as writing the firmware etc…. right?

I had planned a full rant at this point but it was over 500 words long! So here are the main points:

I asked him politely for advice

He went on defence mode and was blunt to the point of being rude; blaming me

I explained to him that he hadn’t sent it in an anti-static bag

He still blamed me

I asked for a refund or replacement

He ignored me

I contacted eBay to complain but it had gone over the 31 days ‘warranty’

There was nothing I could do!

Now being an Aberdonian, you can probably imagine how I felt about that… I think I even used some words which Mrs Geek taught me when I made the Nickel Acetone ;o)

I am not going to name and shame the eBay seller over the internet but if you are thinking about ordering an internal SD2IEC drive from eBay, I will gladly let you know who he is through a personal message or email.

Unfortunately that was only the start of my troubles installing this modification!

I ordered an internal SD2IEC drive from TFW8B.com and was delighted with the product and support documents. I have bought from them before and have always been delighted with the quality of product and support documents offered.

So I got to work designing my 3D Printed housing sousing my Vernier callipers I measured the cartridge port at the rear of the C16 and made my rough sketch on paper… apologies for the ‘rough’ rough sketch

After I had my initial design sketched out on paper, I designed the 3D housing using Solidworks

I printed it out using my resin 3D printer

Then I populated the 3D Housing with the switches, LED’s and SD2IEC drive.

As this mod blew up my C16, I am not going to go into any detail about soldering everything together as I will cover that with the redesigned housing.

But once fitted it looked like this.

I have to admit that it looked fantastic and worked flawlessly but I made a couple of silly judgment of errors when designing and testing the C16.

The first mistake I made was when I foolishly laid the C16 on the carpeted floor for a prolonged test; this resulted in restricted air flow getting into the C16 from the bottom slots on the C16.

My second mistake was not having any air holes or slots on the 3D printed housing design. This as you can see blocked the large slot in the rear of the C16 where air would usually enter or leave the C16.

This resulted with my C16 crashing after an hour or so. I reset the C16 but was greeted with the black screen of death! I had killed my C16! I was gutted!

I tried my Diagnostics Rom which didn’t even get past the initial test; so I dug out my oscilloscope to have a look at the waveforms on the usual suspects.

During my earlier mod when I re-capped the C16, I placed heatsinks on the TED chip as well as the PLA chip which according to the research I did were the two most commonly overheated chips on the PCB. As I had already protected them with heatsinks I decided to have a look at the MOS8501 CPU first.

Poking around with my oscilloscope I found that pins P0-P7 had no waveform whatsoever!

Pins D0-D7 were also looking pretty suspicious

I think I had just fried my CPU… probably the most expensive chip on the PCB!

Looking on eBay, I found that there were a few options; the first being spending about £80 on an original MOS8501 from Hungary… I’m an Aberdonian so that was a horrifying thought to me.

The second option was to buy a MOS 8501/7501 conversion PCB which uses the 6510 CPU used in the C64. But, and it was a big but for me, this also required a modified Kernal ROM. As I was planning to fit a JiffyDos Kernal ROM I couldn’t use that option either.

Then I stumbled across this device on eBay from Germany

This claimed to be a drop in device which uses the 6510 chip and runs it through a microprocessor.

At just over £30, this was a fantastic deal considering the price of a 6510 alone on eBay in the UK will set you back around £35-40!

Once the chip arrived, I eagerly stripped down my poorly C16.

Then I removed the old MOS 8501 CPU; the easiest way to do this is to lever the chip out from side to side using something flat. A thin plastic spudger would be the best thing for this job but I didn’t have one to hand so I used a thin metal scraper. There are other tools you could use for this such as a chip puller but I do not like using them as it is in my opinion easier to damage the chip when extracting it.

Fit the replacement CPU; I have highlighted the notch in the first picture shown below.

With that done I nervously plugged my C16 up to the TV… would it work?

I switched it on…

And…

Success!! It even showed that the system had an upgraded 64k RAM (I have to admit to being a wee bit nervous about that)

Great, we are now on a level playing field again… Time for the SD2IEC install!

As my attempt at a 3D printed housing had failed I considered putting breathe slots on to my design but then decided against it as I didn’t want to risk overheating again, I turned to the internet to see if anyone had come up with a design for the C16.

My searching came up with a blank but there was a design for the C64 which can be found on Thingiverse. You can find the link to it on the TFW8B.com website but I will give you a direct link to it below.

HTTPS://www.thingiverse.com/thing:3761804

This is a brilliant piece of 3D print design from gazmarshall and I thank him very much for making it public.

As it was for a breadbin C64, I figured that it would be the same footprint as the C16 faceplate so I set to work redesigning. I had to fill the holes for the controllers, power switch and the power supply then I had to carefully measure the locations of the controller ports, reset switch, power switch and power supply so that I could extrude cuts into the design.

As I wanted to have access to the SD2IEC reset switch and LED’s I did a bit more measurement and found that I could fit them to the top right hand side of the faceplate. I even added another switch ‘up’ should there be any multi disk games for the C16.

Below is a picture of my version of the faceplate drawn on Solidworks.

This was the second attempt as I found that Gazmarshall’s design had supports on the rear of the faceplate which wouldn’t allow the print to sit flush on the C16.

Below is a link to my final design of the faceplate on Thingiverse

https://www.thingiverse.com/thing:5410947

Below is a picture of my 3D print which I did on my Prusa filament printer. Unfortunately I don’t have any pictures of this process as as you can see I have already fitted the LED’s.

Now it is time to populate the faceplate and wire up the SD2IEC to the C16

Tools required:

Soldering Iron

Cutters

Pliers

Wire Strippers

Heat Gun

Cross Headed Screwdriver

Components Required:

Green 5mm LED

Red 5mm LED

2 X Rubber LED Holders

2 X 330Ω Resistors

2 X 4 Way Pin Header Sockets

2 X 3 Way Pin Header Sockets

(Although I used 2 X 15 Way sockets and cut them down to size)

2 X Push to Make Chassis Mount Switches

3mm Heatshrink Sleeving

1.5mm Heatshrink Sleeving

Equipment wire of your choice (I would recommend using either 7/0.2mm or 10/0.1mm wire)

The colours I used were

Red

Black

Yellow

Purple

Blue

Green

Either come Kapton or insulating tape

Solder

2 X Small Self-Tapping Screws

Double row Pin Header Strip

Fit the Green and Red LED’s into the rubber LED holder.

Then trim the legs of the LED’s; ensure that you cut the shorter Cathode leg shorter than the Anode leg as this will help you when you come to solder on the wires and resistors.

Fit the LED’s to the faceplate

Trim one leg of both resistors to about 5mm from the body of the resistor.

Then tin the trimmed leg of both resistors as well as all of the four legs of the LED’s.

Solder the resistors on to the Anode (longer leg) using a butt solder joint.

Trim the other legs of the resistors to about 5mm from the body of the resistor.

Then tin both legs of the resistors.

Now strip, twist and tin about 5mm insulation from the red wire.

Then solder it on to the Anode (Long leg) of the Red LED.

Strip, twist and tin about 5mm from the Green wire.

And solder it to the Anode of the Green LED.

Now strip, twist and tin 5mm insulation from 2 lengths of black wire.

And solder them on to the Cathodes (short legs) of the LED’s

Cut 2 X 30mm strips of 1.5mm Heatshrink Sleeving and another 2 X 30mm length strips of 3mm Heatshrink sleeving.

Then fit the 3mm sleeving over the Red and Green wires and the 1.5mm sleeving over the black wires; ensure that no bare wires are showing then shrink the sleeving with your heatgun.

Now measure and cut the four wires to length then use 3mm heatshrink sleeving for my cable management instead of cable ties. Simply cut about 5-10mm lengths of sleeving and slip it over all four wires at regular intervals then shrink down with your heatgun.

Now it is time to solder the wires to the pin header sockets; if like me you don’t have a 4 way socket and you are cutting down from a 15 way socket, I recommend cutting the socket in the middle of the 5th pin.

Now place one of the four way pin header sockets into some helping hands and tin all four pins.

Cut four strips of 1.5mm Heatshrink Sleeving to around 10-15mm in length.

Below is the wiring diagram for the LED Pin Header Socket.

Strip, twist and tin 5mm insulation from all four wires then solder them on to the socket as shown in the diagram; don’t forget to fit the heatshrink sleeving before soldering.

Then shrink the sleeving over the pins ensuring that no visible conductors are showing.

Now, place a push to make switch into the helping hands then strip, twist and tin about 8mm of insulation from a black wire.

Thread the tined wire through the hole in the solder terminal of the switch.

Then a wee tip; use a pair of cutters or pliers to hold the wire in place as shown in the picture below. The tension on the wire prevents it from moving when soldering.

Solder the Black wire then repeat the process with a yellow wire.

For the second switch, I used black and purple equipment wire.

Cut about 20mm of 3mm hearshrink sleeving then fit them over all four solder terminals and shrink using your heatgun.

Now fit the switches to the faceplate.

Then cut the wires to length and use 3mm heatshrink sleeving for cable management as shown earlier.

Cut 3 X 20mm lengths of 1.5mm Heatshrink Sleeving then strip twist and tin about 5mm insulation from each wire.

Take the 2 black wires and twist the stripped wires together then tin.

Then fit the sleeving over the now three wires.

Here is the wiring diagram for the Switch Pin Header Socket.

Solder the wires as shown below then shrink the sleeving over the pins of the socket.

Taking the double row pin header strip, use your pliers to break off a 6 way header (which will give you a 2X3 way header) then do the same to give you an 8 pin header (2X4)

Below is a picture of the solder pads we are looking to solder the pin-header strip.

Carefully line up the pins on the PCB and solder an end pin first, check that it is sitting straight and if so solder the remaining pins. Repeat this for both pin header strips.

Now fit the SD2IEC PCB on to the 3D print; it is a tight but it will fit!

After it has been secured in place with the plastic clip, wire up the Switch pin header socket as shown in the diagram below. This fits on to the pins on the solder side (underside of the PCB) and on the 4 pin header strip.

Note that the black wire goes to the outside pin on the connector.

After that, fit the LED pin header socket as shown in the diagram below. This fits on the component side of the PCB

Note that the black wire goes to the outside of the PCB with the Green wire next to it.

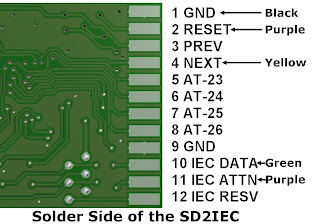

Now it is time to solder the 5 wires from the SD2IEC PCB to the motherboard of the C16

The 5 wires in question are DATA, CLK, ATTN, +5V and GND.

Below is the wiring diagram with the colours I decided to use for this part of the modification

Use the same process as before when soldering on to the pin header sockets.

Strip, twist and tin about 5mm insulation from each wire then solder on to the 3 way pin header sockets; remember to add 1.5mm heatshrink sleeving to insulate the pins on the header sockets.

Below are the two wiring diagrams for the header sockets.

And here are the wires soldered on to the pin header sockets.

Use 3mm heatshrink sleeving to group the wires as part of the cable management.

And route the 5 wires as shown below.

For soldering the wires on the solder side of the PCB, you will need to cut the wires to length. The diagrams below will show you where the solder points are so if you trim all 5 wires to the maximum length then we can go on and solder each wire in turn.

I used Kapton tape to fix the wires to the PCB then soldered the wires from right to left, starting with the Green DATA wire.

Add fresh solder to the 5 highlighted solder points (I have colour coded them using the colours I used for each wire)

Then cut the Green wire to length, strip, twist and tin about 2mm insulation from the green wire then solder it on to the highlighted solder point.

Repeat the process for the remaining 4 wires and fix everything down with some Kapton tape; I covered the solder points completely with Kapton tape.

Now fit the 3D printed faceplate to the C16

Then screw down the motherboard to the bottom half of the C16. You will need some small self-tapping screws to fix the new faceplate; the old ones were machine type screws which fitted into a threaded hole on the old metal faceplate.

Now it is time to fit the 5 wires to the SD2IDE PCB, below are the wiring diagrams I used.

Fit the connector to the underside (solder side) of the SD2IEC; note that the pin on the outside of the board does not have a wire leading from it. The Green wire is in the middle and the Purple wire is towards the middle of the SD2IEC.

Now fit the connector to the top side of the SD2IEC PCB. Note that the Black wire fits on to the pin on the outside of the PCB and the Red wire points towards the middle of the PCB.

Once done, reassemble the rest of the C16; it is time to test!

Hook your C16 up to the TV and switch on; I am always a wee bit nervous when it comes to testing for the first time.

The C16 lives! Good start, now let’s test the SD2IEC.

Type LOAD”FB16”,8

Then press RETURN

Note that the Green status LED will flicker as it is loading from the SD Card.

Once loaded, type RUN then press the RETURN key.

The FB16 menu should look like this.

Use the cursor keys to select a letter then Press RETURN. Then use your cursor keys to select the software you wish to load.

I chose Raider; as you can see there is a > next to Raider press RETURN to select the game.

Raider loaded flawlessly!

But I am rubbish at it!

Now to test the SD2IEC reset switch.

Reset the C16 with the C16’s reset button.

Then press the SD2IEC reset switch; in this install it is the push to make switch towards the rear of the C16.

Type LOAD”FB16”,8 then hit RETURN as before.

And hopefully you will be greeted with a screen like this.

Type RUN then press RETURN and the FB16 menu should load up.

I chose Manic Miner for the second test and again it worked flawlessly!

Again, I am pretty rubbish at this game… I think a pattern is forming… rubbish at most games ;o)

Now let’s see what happens if we reset the C16 and try loading the FB16 menu without pressing the SD2IEC reset switch.

As you can see, there is an error message

?FILE NOT FOUND ERROR

Press the SD2IEC Reset push to make switch and try again then you should be able to load the FB16 menu after that.

The last game I tried during this test was Invaders and guess what… I was pretty rubbish at this game as well!

Thank you for taking the time to read this entry; it is rather long but I wanted to include the part about me ‘killing’ my C16. We can’t always get things right first time and it was good to get the oscilloscope out for testing the CPU whilst fault finding the C16.

I will put this down to experience; I have since read that the C16 kind or relies on the cartridge port for ventilation, I wish I had read that before attempting this mod!

Below are 2 youTube clips showing this modification from start to finish

I hope that you have found this useful; if you have any questions then please feel free to leave a comment or email me directly at

Next up – Dual JiffyDos Kernal ROM

- Get link

- X

- Other Apps

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

.jpg)

.jpg)

.jpg)

Comments

Post a Comment