Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

ZX Spectrum +2 (issue 3 – Grey version) Re-Cap and Heatsink Modification

In this entry, I am performing a complete re-cap of an

issue 3 Zx Spectrum +2 (grey) from start to finish. Included in the entry are

the locations of the capacitors in question as well as locations of the vias

for de-soldering.

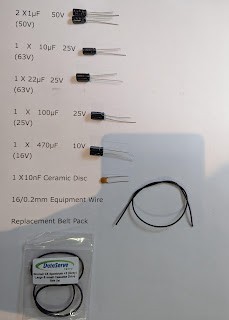

Components required for this mod are:

4 X 1uF 50V Electrolytic Capacitors

1 X 4.7uF 25V Electrolytic Capacitor

1 X 10uF 25V Electrolytic Capacitor

5 X 22uF 25V Electrolytic Capacitors

2 X 47uF 25V Electrolytic Capacitors

2 X 100uF 25V Electrolytic Capacitors

2 X 220uF 16V Electrolytic Capacitors

A 40 pin thermally adhesive heatsink

Heatsink compound

IPA Alcohol

Solder

Tools required:

Soldering Iron

Cutters

Pilers

De-Soldering Gun or tool

Screwdriver

Solder wick (advisable but not necessary)

Toothbrush

And

I also had issues with my de-soldering gun blocking up

for the first time.

As well as the re-cap, I thoroughly cleaned the PCB

with IPA alcohol as this is the last modification I am doing on the circuit

board.

Finally I renewed the heatsink compound on the ULA chip

and fitted a new 40 pin heatsink to the Z80 processor chip.

So let’s get started!

Firstly strip down the +2; I have explained how to do

this in other entries but if you are struggling leave a comment and I’ll gladly

help.

Before we start this mod it is a good idea to

familiarise yourself with Electrolytic Capacitors. Below is a picture of a 10uF

25V Electrolytic. I have labelled all the relevant markings and features.

It is very important that you fit replacement

electrolytic capacitors in the correct polarity. The ZX Spectrum +2 (issue 3)

has very good markings on it which will tell you where the positive leg of the

capacitor goes.

However manufacturers can still get things wrong as was

seen when the factory fitted incorrect transistors into the same system so it

is always good to check orientation before you replace.

A good way to check that you are fitting the

replacement capacitor in the correct orientation is to take pictures and also

do them one at a time (this should also ensure that you fit the correct value

of capacitor)

Faulty electrolytic capacitors are usually easy to

detect; if they are in the process of ‘blowing up’ you may see a bulge on the

very top ‘aluminium’ part of the capacitor. Other tell-tale signs are leakages

of electolyte at the base of the capacitor; again this is easy to detect with a

simple visual inspection.

A quick visual inspection showed no signs of damage to

the capacitors on the +2

But, that doesn’t mean that the capacitors are in good

working order.

I decided to start the mod from left to right on the

PCB and the photos below will show you the order that I replaced them in.

Starting with C81; it is a 100uF 16V electrolytic and

its location can be found below

But for de-soldering purposes, we really need to know

which vias (pads) to de-solder so I have highlighted them in the photo below.

I will go over the whole de-soldering practice with you

on this capacitor (including problematic capacitors)

To help you de-solder, it is a good idea to add fresh solder to the original solder joints. This adds flux and should make reflowing the solder a whole lot easier.

Now it is time to desolder:

You will need some kind of de-soldering tool; one of my

most recent additions to my workshop area is a De-Soldering Gun which I am

extremely happy with. But I know that they are expensive and not everyone can

justify the expense (you can pick up a cheap de-soldering tool as seen in my

earlier entries for a couple of pounds on ebay)

De-solder the two highlighted vias.

Once de-soldered, carefully remove the capacitor (watch for any physical resistance when pulling it from the PCB) If need be, add fresh solder to the vias then try the de-soldering process again. In some instances, I found that I had to use my soldering iron when pulling the capacitors from the PCB.

Once removed, solder in the replacement 22uF capacitor

ensuring that you place the capacitor in the correct orientation.

Once soldered, trim the legs of the capacitor just

above the solder joint with your cutters.

The remaining capacitors are done in exactly the same

way so I will just highlight the locations of the capacitors and vias in the

order I replaced them in.

Next up is C29 which is a 1uF 50V Electrolytic

Capacitor, below is the location of the capacitor on the component side of the

PCB and below that the location of the vias.

The next capacitor I replaced was C5 which is a 220uF

16V Electrolytic Capacitor.

C68 caused me some confusion as I had a 100uF capacitor on my PCB yet both the schematic diagram and capacitor kit suggested that this was a 220uF 16V.

C6 was next which is a 100uF 25V Electrolytic Capacitor.

Then I replaced C49 which is a 1uF 50V.

Next up was C50 which is also a 1uF 50V capacitor.

Then I replaced C36, again a 1uF 50V Cap.

After that I turned my attention to C39, a 4.7uF 25V

Capacitor.

Then I replaced C41, a 100uF 25V Electrolytic

Capacitor.

C30 was next which is a 47uF 25V Capacitor.

Followed by C23, a 22uF 25V Cap.

C25 was next which is a 47uF 25V Capacitor.

Then C24, a 10uF 25V Electrolytic Capacitor.

C62 was next on the list which is a 22uF 25V

Electrolytic Capacitor and I found that it was quite awkward to de-solder.

I then replaced C63, also a 22uF 25V Cap and had a

similar problem de-soldering it.

Then I replaced the 100uF capacitor fitted for C68

earlier with a 220uF 16V capacitor.

The final capacitor in the Capacitor kit was C52 which

was originally a 22uF 25V Electrolytic Capacitor. As I had replaced that

capacitor with a 100uF 25V Capacitor during my Jailbar and Ghosting Fix (see

earlier entry) I decided to leave the 100uF Capacitor in place. If you require

to replace C52, I would recommend replacing it with a 100uF 25V as this will

help to improve the picture quality of the video on your TV set.

Locations can be found below.

After replacing all the Electrolytic capacitors and

with no further plans to repair or modify the circuit board, I gave both the

solder side and component side of the PCB a good clean with some IPA Alcohol

and a toothbrush.

Cleaning the solder side of the PCB with IPA and a

toothbrush does remove (or loosen) flux residue left over from soldering both

new soldering and factory soldering. However it does leave a sticky residue all

over the PCB. I found that the best way to remove the mess was to use some

fresh IPA and a cotton bud.

After I thoroughly cleaned the PCB, I turned my

attention to the heatsink on the ULA. As the ULA for the ZX Spectrum +2’s are

quite rare and expensive to replace, it is a good idea to replace the old

heatsink compound on the heatsink and ULA.

To remove the old heatsink, I gently twisted the

aluminium clip with a pair of pliers then lifted it from the ULA IC.

I am very glad that I decided to do this wee

modification as there was hardly any heatsink compound on the ULA or heatsink

at all as can be seen in the photo below!

Clean the old heatsink compound off both the heartsink

and ULA chip with some IPA and a cotton bud.

Then apply fresh heatsink compound to the heatsink.

After that, refit the heatsink being careful when bending the aluminium clip back into position as this is easily broken.

Now clean the top of the Z80 CPU chip with some IPA and

a cotton bud.

Then fit the new 40 pin thermally adhesive heatsink to

the top of the Z80 chip.

And you should have a PCB looking like this.

After that, rebuild the +2.

Then test!

I even think that the picture quality has improved slightly!

Thank you for taking the time to read this entry, below

is a youtube clip of the complete process from start to finish.

If you have any questions or queries about this mod

then please feel free to leave a comment or email me directly at

Thank you again.

- Get link

- X

- Other Apps

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

Comments

Post a Comment