Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

ZX Spectrum +2 (issue 3, Grey) restoration, repair and modification – Deep Clean and replacing the 7805

Hello and welcome to the final entry in my £5 ZX Spectrum +2 (issue 3, Grey) restoration, repair and modification project.

Below is a picture of the completed ZX Spectrum +2 in all its restored glory!

So far I have covered:

Design and fitting of a TZX Duino Amplifier

Sorting a flickering picture issue whilst using a SCART lead

Making a ZX Diagnostics Rom

The Raining Picture (Umbrella) fix

The AY Sound Leveling Fix

Removal of Jailbars and Ghosting Fix

Cassette Drive Overhaul

Recap and Heatsinking

And finally, todays entry is a Deep Clean as well as replacing the 7805 with a 2A version.

Tools required for this mod include:

Cutters

Pliers

Soldering Iron

Scalpel

Ruler

Screwdriver

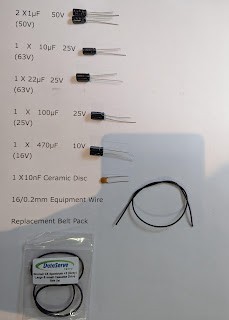

Components required:

L78S05CV

Heatsink Compound

Double sided tape

Rubber feet

Heatshrink sleeving

Superglue

Epoxy Resin

IPA

Lets start by stripping the +2 down

I was lucky enough to have the original serial number still attached to my Spectrum and as I was going to be thoroughly washing the case of the computer I decided that it would be a good idea to remove the serial number then stick it on after I had cleaned the Spectrum.

I removed the serial number very carefully with a spudger as shown in the picture below.

Then I removed the two rubber feet still attached to the bottom of the Spectrum; I don’t know why two rubber feet were missing from this computer when I bought it but a replacement pack set me back about £7 from Mutant Caterpillar (I thought that this was a wee bit pricey to be honest but as they are not in general production any more, I can understand why they were the price that they were)

As I was going to wash the case of the Spectrum I had to strip absolutely everything out of the computer starting with the cassette drive unit which also had my TZX Duino Amplifier fitted alongside of it.

I started by removing the TZX Duino amplifier

Then I removed the five smaller cassette drive screws

There is a longer self tapping screw which needs to be removed and that is located here

After that I removed the power LED PCB from the case, this is only held on by one self tapping screw and it can be found by flipping the drive unit over as seen in the picture below.

The only other thing preventing the drive unit from being lifted out was my TZX Duino amplifier input jack socket. To remove that I needed to use some fine pointed pliers to get a grip on the locking nut.

Next up was the removal of the keyboard from the case; this is done by removing the four highlighted screws shown below.

It was whilst I was removing these screws that I noticed that one screw wasn’t coming out. This indicated to me that there must be some damage to the screw hole boss on the case of the +2. So I carefully lifted the keyboard out.

And found that indeed the screw hole boss was broken. The easiest way to remove the broken boss is to simply hold the boss with a pair of grippy pliers and use a screwdriver to unscrew the screw.

I put the broken boss in a safe place and would repait it later.

The next thing to do was to remove the metal backing plate from the keyboard and this can be done by removing the four highlighted screws shown below.

Then carefully unclip the backing plate away by gently pushing on the black clips and prising the plate away at the same time.

The next thing to remove was the keyboard membrane; although the membranes of the +2 are far superior to that of the ZX Spectrum 48k’s, care should be taken when removing them as they can easily be torn. The membranes themselves are made up of two layers and it is a good idea not to separate them (unless they need cleaning individually)

The membrane on this Spectrum +2 is in surprisingly good condition; almost like new in fact so there was no need to clean it at all.

I then dusted the plastic keyboard housing with a soft paint brush then started to remove the keys.

This is done by using a small screwdriver to gently lever the plastic locking clip away whilst pulling the key away from the other side. Again care should be taken when doing this as sometimes the plastic in the keys become brittle and are easily broken.

When removing the keys it is a good idea to separate the keys from the springs so I used two old ice cream containers for this purpose.

When you come to the larger keys you will find that they have a metal supporting bar fitted; the easiest way to remove these is to lever the ends out first (from the grey plunger part of the key) then gently pull the bar away from the tiny black plastic clips on the housing of the keyboard.

The Enter key is the only key with a different spring and has a smaller diameter so that is something to keep in mind when you come to replacing the keys after the cleaning.

Removal of the keys is just a repeat of the process described above.

Once all the keys have been removed, it is time to give them a clean; I am fortunate enough to have an Ultrasonic Cleaner so opted to use that but cleaning the keys can easily be done by using soapy water and a toothbrush.

I used ultrasonic cleaning solution for this purpose but could have simply used water. My ultrasonic cleaner also has a heater but it is a good idea not to use this for cleaning plastics as the ultrasonic cleaning process will also heat up the solution as it cleans. If you add more heat to the process then you can easily overheat the keys which could result in warping the keys.

I set the cleaner to five minutes and prepared my workbench with paper towels for the drying process.

It is a good idea to dry the surface of the keys with a paper towel after cleaning as sometimes you can be left with watermarks on the keys if allowed to simply dry naturally.

Then sit the keys on some paper towel and allow to dry naturally.

Next up were the springs; I cleaned them in exactly the same way; five minutes at room temperature without the heater being switched on the ultrasonic cleaner.

Then sit the springs on some paper towel and allow to dry naturally.

With the keyboard drying, I then turned my attention to the case of the +2. Firstly I removed the cassette lid from the top of the +2. This is done by removing the screw and spring shown below.

Then gently lever the hinge clips on the underside of the case until the cassette lid is free to simply slide out.

And here we have a completely stripped top part of the ZX Spectrum +2

With everything stripped down it was time to clean the +2. I did this using soapy water and a toothbrush. When cleaning the top of the +2 I was careful not to brush too hard on the painted parts (the red Sinclair and 128K as well as the silver ZX Spectrum +2) as the paint can easily be worn away by excessive brushing.

I started with the keyboard housing as shown below.

And I used a cotton bud to clean out the key holes on the housing.

After that I cleaned the cassette lid.

Then the top of the +2

And finally the bottom half of the +2

As with the keys, it is a good idea to rinse then dry the plastic with a paper towel to reduce the chance of any watermarks on the case.

Then set aside and allow the plastic to dry out completely.

After it had dried, I turned my attention to the broken screw hole boss. I used superglue to stick the boss back on to the case of the +2 but in my experience this is never strong enough to fix the boss on permanently so I used epoxy resin to strengthen the boss as the base. As shown in the pictures below.

Set the case aside and allow the epoxy resin to cure; I used quick setting epoxy for this purpose which claimed to cure completely in around 20 minutes. However as there was a thick (ish) layer of epoxy at the base of the boss, I knew that this would take a little longer to cure.

As the keys and springs had dried out completely I turned my attention to refitting the keyboard. When refitting a keyboard, I like to lay out the keys in the order of the actual keyboard as shown below.

Remember to fit the springs to the keys before fitting them in place.

After fitting the springs the keys simply click into place by gently pushing down on the key until you hear a satisfying click.

One thing to remember is that the Enter key has the smaller diameter spring so ensure you fit the smaller spring to that key.

After fitting all the keys, you should have something looking like this

Now to fit the support bars to the larger keys.

Turn the keyboard housing upside down then fit the bars.

I started with the space bar as this looked like the only different supporting bar.

Fitting it is relatively simple; I slid the ends of the bars into the slots on the grey plastic plunger part then used a pair of tweezers to slide the middle of the bar into the black plastic clips on the keyboard housing. Again, care should be taken when doing this as the black plastic clips are rather small and pretty fragile.

I had a whole lot of trouble fitting the Extend Mode supporting bar (shown below)

Until I finally realised that the supporting bar for that key was slightly deeper in width... It only took me about five minutes LOL

Correct supporting bar fitted now!

Once done you should have something looking like this

Now refit the keyboard membrane; again, try not to separate the two layers of the membrane when doing so.

Then refit the metal backing plate; this simply pushes on with a satisfying click sound when doing so. Ensure that all black clips have been seated correctly and that the backing plate is sitting flat.

Then refit the four small fixing screws on the holes beside the membrane tails as shown below.

After that I refitted the cassette lid to the top panel of the +2. Slip the hinge part through to the underside of the +2 then gently lever the hinge pins into position.

Then refit the spring; the picture below shows the correct orientation of the spring.

Secure the spring with the fixing screw then refit the keyboard.

Care should be taken to fit the screws in the correct position as failure to do so will result in you not being able to fit the main case screws to the +2. A reminder of the positions of the crews is shown below.

Now we can refit the cassette drive and TZX Duino Amplifier.

Start off by refitting the TZX Duino Amplifier input socket. This is done by using a pair of fine nosed pliers and carefully tightening the nut with them (you can buy a proper tool for this purpose but I do not have one in my toolkit)

Then refit the power LED PCB in the position shown below.

Next refit the TZX Duino Amplifier by simply pushing the PCB’s fixing holes on to the PCB stand off’s

Then refit the actual tape drive; below is a picture of the locations of the 5 smaller screws.

The longer self tapping screw gets fitted in the position below

Once fitted I turned my attention to the bottom half of the +2; I started by sticking the serial number back on. As the serial number had lost its ‘stick’ I decided to use double sided sticky tape. I used my thinner tape for this and it was almost a perfect fit.

Trim away the excess tape with a scalpel

Then fit the serial number back on to the bottom of the +2 as shown below

Then fit the new rubber feet by pushing them firmly into the holes on the bottom half of the +2.

After that, refit the main circuit board to the bottom half using the 6 smallest self tapping screws

Having done that, I decided to replace the old 1.5 A rated 7805 with a new 2A rated version (L78S05CV) Although I have never had a 7805 fail in the past I thought that as I had a new one in stock at home that it wouldn’t do any harm.

My camera didn’t pick up a whole lot of this part of the modification as I had it out of position but it is pretty straight forward. The pin out on the new L78S05 are exactly the same as the old 7805 so swapping the wires over is easy; just make sure that you solder the wires in exactly the same position.

I am unsure whether all +2’s have the same colours of wires but in my case the input wire was brown, GND was Black and the Output was Red. Below is a picture of my wiring diagram for the 7805

Firstly remove the old 7805; I found that the screw was pretty tight so be sure to use an appropriate sized screwdriver to remove the screw otherwise you will risk chewing up the head of the screw.

Then clean the old heatsink compound from the heatsink with some IPA

Prepare the new L78S05CV for soldering by trimming the legs slightly and tinning each leg at their ends.

Then slide the old insulation sleeving from each leg of the old 7805 then transfer and solder the wires one at a time on to the new L78S05. I had planned to use some new heatshrink for this job but the old sleeving was in very good condition so I opted to use the original sleeving instead.

After that, apply some heatsink compound to the new L78S05.

Then fix the new 7805 to the heatsink as shown below

All we have to do now is to reassemble the +2 and test.

Fit the voltage regulator connector

Then fit the keyboard membrane to the PCB

After that fit the cassette drive connector to the PCB, fit the lid and screw in the six case fixing screws.

As a wee treat I bought new screws for this purpose; I wanted the +2 to be as authentic as possible so bought new black screws for the job. I found that 12mm M3 Self Tapping screws were the correct size and length and managed to source 100 of them from Aliexpress for about £1.92 plus shipping.

Now all I had to do was test the system. Below are some pictures of the finished +2, plugged in and working!

I am absolutely thrilled with the finished product here; it is picture perfect and sparkly clean. I have had a blast working on this project and am a little sad that it is now over. Here’s hoping that this +2 will continue to work for at least another 35 years!

A youtube clip of the complete process can be found below.

Thank you again for taking the time to read this very long entry. If you have any questions or queries about this mod or any of my others please feel free to leave a comment or email me directly at

- Get link

- X

- Other Apps

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

Comments

Post a Comment