Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

Commodore C16 Re-Cap and replacing the 7805 Voltage Regulator

Welcome to the first in a series of posts in which I am

going to restore, repair and modify my Commodore C16.

As the C16 is a very old computer, it is always a good

idea to replace the electrolytic capacitors due to the fact that they are

components most likely to fail (with the exception of the TED chip) With age,

they are prone to drying out or leaking and can cause a whole lot of damage

when they do so.

The C16 only has 8 electrolytic capacitors so this is a

relatively quick job.

I decided to also replace the 1A 7805 with a 2A rated

version of it (L78S05CV) as this has a bigger heatsink on it and will cope

better with the high current draw of the C16.

A YouTube clip of the complete process from start to finish can be found at the end of this entry.

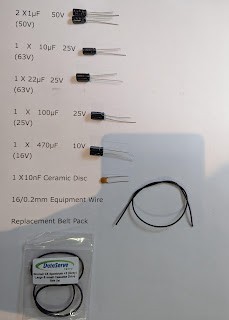

For this restoration you will need the following

components:

1 X 1uF 50V Electrolytic Capacitor

6 X 10uF 25V Electrolytic Capacitors

1 X 47uF 16V Electrolytic Capacitor

1 X L78S05CV (2A) Voltage Regulator

Heatsink Compound

Solder

IPA Alcohol

Tools required:

Cutters

Pliers

Screwdriver

De Soldering tool

Solder Wick (advisable)

5mm spanner

Cotton Bud

Firstly we have to strip down the C16; This is the

first time I have been inside this computer so this was just as much a learning

curve for me as it hopefully is for you. I will highlight things which I found

out along the way.

Remove the three main fixing screws on the underside of

the C16.

Then open up the C16 as shown below

Remove the Power LED connector from the PCB; note that the Red wire is on the left as you look into the C16 from the front.

Then remove the long 20 pin Keyboard connector; I found

that the best way was to wiggle it out from side to side but be careful not to

bend the pin header pins on the PCB.

Remove the top of the C16 and then start removing the

PCB screws.

There are 8 PCB screws in total, 6 of them are of the

self tapping variety and are highlighted below.

And the other 2 are machine type screws which means that they are threaded (possibly M2.5) and are highlighted in the photo below.

After the PCB has been removed we need to take off the

RF shield ; this is done by bending up the metal clips which hold it to on the

component side of the PCB. I have highlighted their locations below.

I used a pair of cutters to gently lift up the metal

clips; care should be taken if using cutters as it would be easy to actually

cut the clip off.

Now we can start replacing the capacitors starting from

left to right, I removed and replaced the capacitors one at a time.

The first Capacitor is C17 which is a 1uF 25V

Electrolytic capacitor.

Below is the location of it on the component side of

the PCB.

And below is the location of the vias we need to

de-solder.

I used my de-soldering gun for the majority of this job

but you could easily use a simple De Soldering tool instead.

After de-soldering, try and ease the capacitor out of

the PCB. Care should be taken doing this as the vias have plated through holes

which mean that there could still be solder in between the layers of the PCB.

I usually inspect the de-soldered vias before

attempting to remove any component.

After my inspection I found that one of the legs still

had solder connected to the PCB so I simply heated up the leg with my soldering

iron and gently pushed it free from the solder. This was adequate enough to

allow me to remove the capacitor.

Then carefully wiggle the capacitor out watching for any

signs of physical resistance which would indicate that the capacitor was still

soldered to the PCB.

Failure to ensure that the capacitor is completely

solder free can and often leads to damaged traces on your circuit board; not

the end of the world but awkward and fiddly to repair and also looks unsightly

once done.

After that, we need to replace the old 1uF 50V capacitor with a new one. It is vitally important that you place the capacitor in the circuit with the correct orientation. See the picture below to remind you.

The photo below shows a typical electrolytic capacitor

with usual markings and meanings.

Place the 1uF capacitor as shown below and push it as

flat on to the component side as it will readily go.

Turn the PCB upside down and bend the legs of the

capacitor out to about 45°; this should ensure that the capacitor doesn’t fall

down when soldering.

Then we have to solder the capacitor into the circuit.

Good soldering practice is to heat both the component leg and via up for around

2-3 seconds using a hot soldering iron (I like to use leaded solder and a

temperature of 330°C)

After both parts are warm enough to melt solder, feed

the solder on to the via and leg once the solder has melted around the via and

leg, remove the solder but keep the soldering iron on the joint.

What you are ideally looking for is the solder to rise

up the leg of the capacitor until you get a curved surface all the way around

the via and leg; this typically takes between 2-3 seconds.

After that, remove the soldering iron.

Once soldered, trim the excess legs of the capacitor

away with a pair of cutters. You are looking to cut the leg just above the

solder joint itself as if you cut into the solder you will weaken the solder joint.

Replacing the remaining capacitors is just a repeat of

the instructions above however I did have some trouble removing a couple of

capacitors which I will detail a wee bit further as we go through the

capacitors.

The next capacitor to replace is C16 which is a 10uF

25V electrolytic capacitor; I had no trouble replacing this one so will simply

show you the location of the capacitor and vias.

C18 another 10uF 25V capacitor was the next one to be

replaced and again I had no trouble removing it.

C19 was next and that is another 10uF 25V capacitor.

Then I replaced C31, a 10uF 25V electrolytic capacitor.

C4 was next and another 10uF 25V capacitor.

The last of the 10uF capacitors gave me some trouble;

C3 was very awkward to remove. Below is are the locations of the capacitor and

vias to de-solder.

The first problem I had was when my de-soldering gun

became blocked; below is a photo of me removing the blockage with the clearing

tool which was the correct size for the nozzle.

But even after clearing the blockage, the de-soldering

gum still failed to clear the solder from the via so I used my soldering iron

to melt the solder on the effected via and gently pull the capacitor free from

the circuit board.

Even after removing the capacitor using the technique

described above, the via still had solder in it so I tried to use solder wick

to draw the solder from the via.

Still no joy! So I tried to remove the solder from the

component side using the solder wick.

But even that didn’t work! Time for some drastic measures.

I applied some fresh solder to the via.

Then used my trusty 20 year old solder sucker!

This did the trick; the via was now clear of solder.

After that it was a simple job of fitting the

replacement 10uF capacitor, soldering and trimming the legs.

The last capacitor to replace is C3 which is a 47uF 16V

electrolytic capacitor. And again this one gave me some problems. Below is the

location of the capacitor and vias.

The main problem I had with it was the fact that the

negative pin was soldered on to the ground plane and although my de-soldering

gun did a pretty good job, it still failed to clear the via of solder.

So I used my tried and tested way of removing the

capacitor; heat the solder on the via and gently pull the capacitor free.

This removed the capacitor but again the via still had

a slight blockage of solder in it.

So I tried using my solder wick again; I prefer to use

solder wick when doing this as it is less destructive than using a de-soldering

tool. The land around the vias can be pretty thin in places and using a

soldering iron and de-soldering tool can easily chew them up.

Using solder wick usually removes this risk as you

simply place the wick over the via and place the soldering iron on the via.

This did the trick first time! So I went on to replace

the 47uF capacitor

After that I decided that I would replace the original

1A rated 7805 with a new 2A rated version of the 7805 (L78S05CV).

Below is the location of the component and vias.

I found that the legs of the original 7805 hadn’t been

trimmed so to make de-soldering easier for myself, I trimmed the legs.

Then I de-soldered the legs.

Next up I had to remove the M2.5 nut and bolt which

fixed the 7805 to the heatsink.

It is not a good idea to use pliers to hold the nut

when removing this as pliers can easily slip and cause damage to the traces of

the PCB. So I prefer to use either a spanner, nut spinner or socket to hold on

to the nut.

In this case I used a 5mm socket.

Remove the heatsink.

Then I found that the 7805 still wasn’t free of solder

so I Solder Sucker instead of my de-soldering gun and this did the trick.

Now clean the old heatsink compound off of the heatsink

using some IPA alcohol and a cotton bud.

Then bend the legs of the replacement L78S05 using

pliers then check to see if the holes line up by placing it temporally on the

PCB with the heatsink.

Now add fresh heatsink compound to the back of the

L78S05.

Before soldering, fit and secure the voltage regulator

and heatsink using the M2.5 nut and bolt using either a spanner, nut spinner or

5mm socket.

The reason I like to fit the nut and bolt before

soldering is that sometimes the 7805 will move when tightening the nut and bolt

and this in turn will cause some stresses and strains on the solder joints.

Then solder.

With all the components replaced it is time to refit

the C16, starting with the RF shield.

Below is the locations of the metal clips to re bend into position.

Better look busy; the gaffer is here to check up on my work!

Bending the clips back into shape is simple; all you

have to do is push them over with your finger.

The next part I found extremely awkward! This was due

to me not taking enough time to analyse how I took the PCB out from the C16.

When I tried to refit the PCB I couldn’t get it to locate properly.

I spent a fair bit of time faffing and fumbling about

until I realised that the bezel has to be fitted in-between the PCB and RF

shield!

I got there in the end!

The PCB and bezel fit perfectly now!

Now we need to secure the PCB with the 8 fixing screws;

remember that there are 6 self tapping screws shown below.

And 2 machine type screws, locations shown below.

Refit all 8 screws.

Then refit the keyboard connector; this can only be

fitted one way as there is a blanked out hole in the socket connector to the

left of the connector.

Now refit the power LED connector; the red wire should

be on the left hand side (pointing towards the middle of the PCB) as you look

into the C16 from the front.

Now refit the lid of the C16 then screw in the 3 main

fixing screws on the underside of the C16.

And here we have a fully re-capped with a new 7805 fitted C16.

Plug everything in and prepare to test; this is always

a nervous moment!

And…

Success! The C16 booted up!

It is always a good idea to leave any re-capped

computer on for a wee while whilst testing as sometimes (especially if you

install a capacitor the wrong way round) it takes a wee while for the component

to fail. So for this purpose I decided to load a game using my Tapuino.

Can you tell which game I am loading?

Looks a bit scrambled doesn’t it? I was a wee bit

concerned at this point as this was the first game I have tried to load on the

computer.

But…

After a bit of patience, and resisting the temptation

to turn off the computer to check that everything was ok on the circuit board…

I was rewarded with this screen.

Can’t beat a bit of good old Monty Mole!

A you tube clip of this modernisation of the components can be found by clicking on the clip below.

Thank you for taking the time to read this entry; I

have learned quite a bit about working on the C16 doing this relatively simple

mod. This should make the other mods I have in mind for this computer a whole

lot easier to do.

I think I am going to attempt to make a diagnostics rom

next so that I can test the system for any faults with the RAM, TED chip etc. I

am also going to fit a heatsink to the TED chip which will hopefully prolong

the life of the machine.

If you have any questions or queries about this mod

then please feel free to leave a comment or email me directly at

alleged_geek@aol.com

Thank you again

- Get link

- X

- Other Apps

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

Comments

Post a Comment