Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

ZX Spectrum +2 (Grey) Jailbar and Ghosting Fix

Whilst testing the AY sound mod, I noticed that there was a bit of ghosting going on when I used the RF output of the +2.

I also noticed some jailbars when the loading screen went black whilst loading a game.

Before I do any modification I like to do extended research about the mod I am intending to do. This involves trawling though the internet to find different ideas or simply to confirm that the actual mod will work.

So after a bit of research and thanks to the many clever ZX Spectrum enthusiasts out there I decided to do both mods at the same time.

Notable people to thank include

JoulesperCoulomb

Jamhamster

The wonderful folks at World of Spectrum

And so many more, too numerous to mention

Many thanks to you all for taking the time to make your findings public!

As I mentioned earlier this is a two part mod; the

first one was the jailbar removal. I stumbled across the simple replace C52

(22uF) with a 100uF capacitor but after a bit of digging, I found a clip on

Jamhaster’s Youtube channel which claimed that adding 1uF capacitors in parallel

with C12 – C19 would improve it further.

Part 2 of the mod was to reduce the ghosting issue which was more apparent when using the RF output of my +2. I remembered seeing a clip on JoulesperCoulomb’s Youtube channel which talked about that so I gave it another look and checked his findings on World of Spectrum and other forums I am a member of.

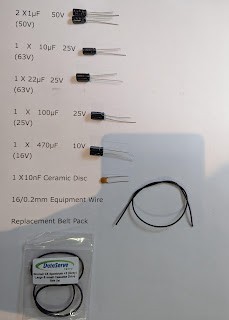

Components required for these mods are

1 X 100uF (25V) Electrolytic Capacitor

8 X 1uF Ceramic Capacitors

1 X 15uH Inductor

1 X 82pF Ceramic Disc Capacitor

I also used a small piece of 3mm Heatshrink Sleeving

Solder

Tools Required

Soldering Iron

Cutters

Pliers

De-Soldering Tool

Cross Head Screwdriver

Heatgun (if using the heatshrink sleeving)

Helping hands (not critical but they did help when soldering the Inductor and Capacitor together)

So let’s get to it!

The first thing to do is to strip down the +2 (see previous entries for the +2 for details)

The next step was to identify C52 which is the 22uF electrolytic capacitor the picture below shows its location on the main PCB (I have also highlighted its orientation)

Below is a picture of the location of the vias to be de-soldered on the solder side of the PCB

Once you have located the via’s the next step is to de-solder.

As I have mentioned before, adding fresh solder to the old solder joints will make the de-soldering process a whole lot easier so it is worth adding solder as shown in the picture below before de-soldering.

After you have freshened up the solder, reflow the solder and use your de-soldering tool to remove the solder from the via.

After de-soldering it is a good idea to check that the legs of the components are completely free from the vias. Failing to do this could result in damaging the traces on your PCB when pulling the component from the PCB.

I used my fingernail to pick at the capacitor legs

Then remove C52 by gently pulling up from the component side. If you feel any real physical resistance whilst pulling the component from the PCB then double check that the vias are free from solder.

Now let’s have a look at the replacement capacitor. We are replacing the old 22uF with a new 100uF 25V capacitor (the voltage doesn’t really matter but I wouldn’t go below a 10V rated capacitor) the important thing is that you get the orientation correct as failure to do so will almost certainly result in a blown up capacitor which could also damage the traces on the PCB as well as do other damage to the circuitry.

Below is a picture of the replacement 100uF capacitor.

As you can see, the long leg is the positive and the short leg is the negative.

Now fit the capacitor to the circuit board. If the pitch of the legs of the capacitor doesn’t match the vias on the PCB do not try and force the capacitor flat on the component side as this will damage the capacitor. A wee tip is to leave a space of about 3mm from the base of the capacitor to the surface of the PCB. However, in this case, my new capacitor matched the footprint of the original capacitor.

Below is the correct orientation of C52.

Turn the PCB upside down and bend the legs of the capacitor to about 45° (this will ensure that the component will stay flat against the component side when soldering)

Then solder both capacitor legs

Finally, trim the excess legs off of the capacitor with a pair of cutters. Try and cut just above where the solder stops as cutting into the solder will weaken the solder joint and could result in a dry solder joint in the future.

After that the PCB should look like this

Now to fit the 8 1uF ceramic capacitors in parallel to the capacitors numbered C12 – C19. The 1uF Ceramic capacitors were pretty cheap and I decided to buy a bag of 100 from ebay instead of a bag of 10 as the difference in price was pennies (I think I only paid about £3 for the 100)

Now let’s have a look at where we will solder them, below I have highlighted the capacitors on the component side of the PCB.

But as I wanted to hide them from view, I decided to solder them directly on to the solder side of the PCB so below is a picture of the vias we are going to solder the capacitors on to.

Now add a liberal amount of solder to all 16 vias on the solder side as we are going to tack one leg on to the via (to secure the capacitor in place) before soldering the capacitor legs properly.

Now prepare the capacitors by bending the legs out to 90°. Take care to leave a wee gap between the paint on the capacitor and the 90° bend as if you go too close to the paint it will result in a broken seal on the paint which will allow moisture to get in to the capacitor which will result in a shorter life span of the capacitor.

Next, pace the capacitor in between the vias, hold it down with your finger then tack one of the legs on to the via (melt the solder on the via and do a temporary solder joint to hold the capacitor in place)

Now we can do a proper solder joint on the other leg of the capacitor.

And then re-solder the first temporary ‘tacked’ solder joint.

Carefully trim the legs of the capacitors as it is quite easy to damage the PCB traces by cutting too close to the traces.

Then repeat the same process for all eight of the 1uF ceramic capacitors

Finally you should have a PCB looking something like this.

Now we come to the second part of this mod, the ghosting fix (or colour bleed fix) in this mod we will need a 15uH inductor and an 82pF ceramic disc capacitor.

I have updated the +2 PCB schematic below with the modification.

Basically we are connecting the 15uH Inductor and the 82pF capacitor in series with the leg of the inductor going to pin 8 of the TEC 2000 IC and the capacitor leg going to pin 17 of the TEC 2000 IC.

Below is a highlighted picture of the TEA 2000 IC chip on the component side of the PCB with arrows pointing to pins 8 and 17.

But as I like to keep the modifications I do to PCB’s away from view, the image below is where we will be soldering the inductor and capacitor on to. Again, I have highlighted the two pins in question.

The next step is to solder the inductor to the capacitor in series; below is a picture of the components ready to solder together. In this picture I am using my helping hands tool to hold the 82pF capacitor. I trimmed both legs of the capacitor and one leg of the inductor as seen below.

Then I tined the ends of the components to be soldered together.

After that I did a simple butt solder joint to connect the inductor to the capacitor.

Finally, I used some 3mm heatshrink sleeving to insulate the inductor and capacitor which should reduce the risk of any short circuiting once it has been soldered in place.

And this is the resulting L C in series circuit.

Now we need to solder it on to the PCB

Place the L C series in position as shown below so that the inductor leg is touching pin 8 of the TEA 2000 IC

Then solder the inductor leg to pin 8

Next, position the other leg of the 82pF capacitor so that it touched pin 17 of the TEA 2000 IC

Then solder

Carefully trim the legs of the components; as I mentioned earlier, it is very easy to damage the PCB traces if your cutters touch the surface of the PCB.

If you have a multimeter it is always a good idea to check continuity between components and pins (even more so when doing the mod on the solder side) I tested continuity between the inductor leg and pin 8 as well as testing continuity between the capacitor and pin 17 of the IC.

After that I inspected the PCB thoroughly using a magnifying glass… my 50 year old eyes (even with glasses) aren’t quite as good as they used to be ;o)

Then refit the +2

Now we come to the best part…. The testing!

I hooked everything up…

…

Powered the +2 up…

…

And…

…

Look at that picture with the SCART output… Beautiful, no jailbars or ghosting!

Success!

Now let’s have a look at a black loading screen using the SCART output

…

…

Beautiful!

Now we come to the interesting part of the test; how well did it fare with the RF output bearing in mind that modern TV’s don’t really like retro consoles or computers…

I switched the TV to the tuner…

And…

…

…

This is what I found.

Here we have a black screen with a much improved image; the jailbars are still barely visible but it is a vast improvement from before the modification.

Now let’s have a look at the video quality of the Uridium loading screen; firstly on the SCART output.

Absolutely perfect… I am impressed!

Now look at the RF output from the +2

It is good but I am now left wondering how good it would look on an old CRT TV… I am guessing that it would look as perfect as the SCART output!

Overall, I have enjoyed this modification… I will admit that the ghosting and jailbar issues on the RF output aren’t perfect but they are a whole lot better than they used to be. But I am completely blown away by the quality of the video on the SCART output of my +2… Wothwhile doing this mod… hell yes!

Below is a link to my youtube channel featuring the complete modification from start to finish.

I hope that you have found this entry useful, if so then please feel free to leave a comment. If not then again please feel free to comment as feedback good or bad is always invaluable.

In my next entry I am planning to refurbish and re-cap the Data-Recorder unit of the +2

Thank you for taking the time to read this entry.

If you have any questions or queries, please feel free to leave a comment or email me directly at

Thanks again

Alleged-Geek

- Get link

- X

- Other Apps

Comments

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

Many thanks for this and the sound level fix!

ReplyDeleteUntil I got to the end, I wasn't sure if this would help for RGB and/or composite on SCART, as you only mentioned the problem with RF at the beginning. Before pics for SCART would have been nice. As well as showing composite before/after. Also, the video link would be handy to have before the photos (or a mention that it exists), for those that prefer vids (others can quickly skip it).

DeleteI'm in the US and excited to get my first Speccy, which will be a +2 Grey.

Have you heard of the "Power Pellett" mod for +2 ghosting? I'm wondering if that is different from what you've done. A refurber on ebay does this.

DeleteHi Jerri,

DeleteThank you again for your comments; I had so much fun restoring and modding my ‘spare’ ZX Spectrum +2. The jailbars on the SCART output weren’t quite as defined as the jailbars found on the RF output but there was a huge improvement with the modifications I did in this entry. If you want to remove them further, a simple re-cap of the electrolytic capacitors also helps (I should have done that modification at the beginning of the series)

The +2 Grey Spectrum is probably the most reliable of all the 128k Speccys and is a great machine to work and play on. I am sure that you will love it as much as I do my one!

I would consider getting a TZX Duino to load the software; You can get them over here for about £20 but I decided to design and build my own version which you will find on my Acorn Electron entry. The only difference between the Acorn and the Spectrum TZX Duino is the firmware which can easily be changed by using the software I have linked in the description on Youtube and in the entry of the blog. You will also find a link to the gerber files should you wish to get your own PCB manufactured I think that I have also included a parts list for the build.

I had a quick look for the "Power Pellett" mod for +2 ghosting but couldn’t find any information about it on ebay or google. Could you send me a link to the ebay listing please? It sounds intriguing and I would love to see and figure out how it works.

Thank you again, good luck with your +2, you are going to love it!

Best regards,

Alleged-Geek AKA Steve