Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

ZX Spectrum +2 (Grey) Raining Picture (Umbrella) Fix

Carrying on with the modification of my £5 ZX Spectrum +2 I decided to do what is known as the ‘Umbrella’ fix. On the ZX Spectrum 128 Toastrack and the +2 there is a known glitch where there is a raining effect on the graphics of certain games during gameplay.

You can see the problem on the picture below where there are loads of horizontal lines running across the screen.

Luckily there is a fix for this thanks to a clever piece of programming from Velesoft. Information and the download link for the code can be found on the link below.

https://velesoft.speccy.cz/zx/umbrella/umbrella.htm

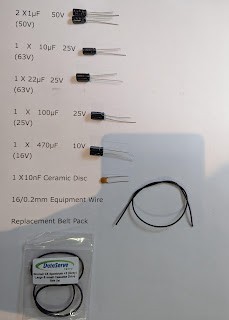

For this fix, you will need the following items.

An Eprom Programmer, my one is a TL866 II Plus shown below (I think I paid about £40 for my one about a year ago but they appear to have gone up in price a wee bit since then)

You will also need a GAL16V8D which can be picked up on eBay from as little as £2 each.

It would be worth ordering a 20 Pin 0.3” pitch IC Socket at the same time as this will make removal of the IC afterwards a whole lot easier. I recommend using a turned pin socket for this as that will make it easier to repair any trace damage done to the component side of your +2’s PCB whilst removing the original HAL IC

Finally you will need a small piece of wire to connect pin 11 of the new GAL IC to pin 28 of the Z80 CPU. For this I used some of my Kynar wire (or wire wrap wire as I know it… again showing my age!) but any old wire will do (within reason)

If you don’t want the expense of buying an eprom programmer, you easily find a pre-programmed GAL16V8D chip online for around £5

Now we have the parts, lets get started!

Firstly I am going to programme the GAL16V8D IC.

Download the zip file containing the new code for the GAL chip; the link below is a direct download for the ZIP file

https://velesoft.speccy.cz/zx/umbrella/gal16v8-new.zip

The file we are interested in is ‘galnew.jed’

Now double click on the XGpro icon to start the programmer software.

Then click on the Select IC box located at the top left of the software window

Then type GAL16V8D in the field as shown below

There should only really be one manufacturer (LATTICE) and the Device we are looking to programme is the one simply called GAL16V8D.

To find out the correct orientation of the IC in the programmers ZIF socket click READ.

A pop up window will then show you where and how to place the GAL chip into the programmers ZIF socket.

As you can see from the picture above, pin 1 of the IC is located closest to the ZIF socket lever. Place the GAL IC into the programmer as shown below.

Then click READ on the software.

If the IC is blank, all the data in the data field should read 1’s as shown below.

Don’t worry if your IC is not blank as the IC as unlike the write once ROM’s I used for the ZX Diagnostics project, the GAL chip can be erased and rewritten as often as you like by simply clicking on the Erase icon within the software.

Now click LOAD.

And then load the galnew.jed file we downloaded earlier.

You should see that the data in the field now has a series of 1’s and 0’s

I scrolled through the data to check that everything was in order then clicked PROG.

When the programmer pop up windows appears, it is important that you uncheck (de-select) the LOCK Bit option

Now Click Program.

And hopefully you will get the same message as shown below.

Now click BACK and have a quick look at the data in the data field.

Now it is time to double check that the IC has been written correctly.

Click READ, then click Read in the pop up window.

Now click BACK to view the data

If you forgot to uncheck the LOCK Bit option, the data will not be correct and it will look different to the image shown below. If this is the case, simply erase the IC and restart the programming process from the beginning.

If the data on the GAL chip looks similar to that above, exit the software… Well done, you have successfully written your GAL16V8D IC with the Umbrella fix software!

Now let’s turn our attention to the ZX Spectrum +2

Disassemble the +2 and have a look for the HAL10H8 IC (IC7 on the Issue 3 PCB) I have highlighted it in the picture below.

Note that all the IC’s have their notches facing south as we look at the PCB.

Below is a close up of the HAL chip.

Now let’s have a look at the solder points on the solder side of the Issue 3 PCB.

Below is a picture of the location of the pins in question as well as a close up shot of the pins we need to de-solder.

Time to get my trusty de-soldering tool out again but before we do so, it is a good idea to freshen up the solder on the IC as this should make de-soldering a whole lot easier.

Now de-solder all 20 pins of the IC; take care doing this as it is very easy to damage the traces on the 35 year old computer.

Inspect the de-soldering job then gently nudge the legs of the IC with something like a spudger to see if they are free.

If there are some legs still soldered you can try to reapply solder then de-solder again.

After that if there are some legs still soldered, you can try and gently nudge the legs to the middle of the via with your soldering iron.

Inspect again (you really don’t want to damage the PCB) and if everything looks free try and gently pry the IC up from the component side. I used my plastic pointy spudger to do this as I did not want to damage the board with a screwdriver.

Disaster! I felt resistance and a cracking sound... Something wasn’t right!

Let’s have a look at pin 5 of the IC leg.

If you look closely you will see what appears to be a blob of solder on pin 5 of the IC. This usually means that a trace or plated through hole via has been removed when lifting the IC from the circuit board! I was beyond the point of no return now so I gently lifted the remaining legs of the IC out of the circuit board. Now I would have to deal with any damage done to the traces. So it was out with the magnifier glass to closely inspect the PCB.

Upon inspection of the component side I lucked out as there were no traces leading to and from pin 5 of the IC! Now the part I was dreading… the solder side! Time to get that magnifying glass out again.

YES! No damage done to the solder side of the PCB… I got lucky! A simple rookie mistake could have ended up with lifted traces. I should have triple checked before trying to lift the IC!

Time to clean up the de-soldered area, for this I used IPA and a cotton bud.

Time to inspect the area again, this time I was looking for solder shards from the de-soldering process as well as any short or open circuits.

All looks good, now time to solder in the IC socket. For this I would always recommend turned pin IC sockets as it is easier to solder wires on to the pins from the component side should there be any damage. The cheaper IC sockets cover the vias completely making it difficult to repair any damage on the component side.

Solder the IC socket on to the PCB; ensure that the notches match the IC and silkscreen print.

We really want the IC socket to be seated correctly and flat against the PCB so a wee trick is to solder the opposite corner pins of the socket then reflow the solder on any raised side whilst pushing gently down on the socket until the socket is fully flat against the surface of the component side.

The reason we do this is because we will be pushing the replacement IC down on to the socket; if it is raised at all there is a possibility that when you push the IC down you can also push the socket pins down which can lift the traces on the solder side.

Solder the opposite corners then check that the IC is seated correctly.

Once happy solder the remaining pins of the IC then inspect the soldering, looking for any short circuits or poor solder joints.

You are also looking to see if the solder has flowed through the plated through vias from the solder side to the component side (this will also confirm that no other damage was done to the through hole traces when de-soldering the HAL chip)

With the IC socket in place it is time to hard wire pin 11 of the GAL16V8D IC (RFSH) to pin 28 of the Z80 CPU (RFSH).

I used my Kynar wire for this but any wire would do within reason (although a heavier gauge will be awkward to solder).

First up, solder one end of the wire to pin 11 of the GAL chip.

Try and minimise the amount of bare wire on the wire when soldering. I like to have it so that the insulated part of the wire almost touches the pin being soldered on to. I also try to ensure that no bare wire is showing on the other side of the pin being soldered on to. This will help avoid any short circuits.

Tin the ends of your wires before soldering them on to the pins (add solder to the bare wire)

Then route the wire to Pin 28 of the Z80, carefully cut the wire to length without damaging your circuit board, tin the end of the wire then add fresh solder to pin 28 of the Z80 (which will make soldering the wire to the pin a whole lot easier) after all that, solder the wire to pin 28.

And this is what it should look like.

After soldering the wire it is always a good idea to check your wiring with a multimeter (either in ohms or continuity modes).

I turned the PCB over so that I could do this test on the component side and connected one probe to pin 11 of the IC socket for the GAL chip then the other to pin 28 of the Z80.

Now fit the GAL16V8D IC to the PCB

Before we fit the IC we will need to straighten the legs; I used my leg straightening tool of which there are several varieties but you could simply roll the legs straight on a flat surface if you don’t have a straightener.

Now fit the IC paying close attention to the orientation (all notches should face south in an issue 3 ZX Spectrum +2)

Below is a picture showing pin 1 of the GAL16V8D IC

And below is a picture showing where Pin 1 of the IC socket on the PCB is.

Now fit the GAL chip then check to ensure that all the pins have located into the socket correctly.

Now it is time to reassemble the +2

Secure the PCB using the six small self tapping screws.

Fit the voltage regulator.

Fit the keyboard membrane.

Fit the cassette PCB connector.

Finally screw in the six case screws.

Now it is time to test the +2… nervous times!

Plug everything in

There is a good picture; if the GAL16V8D chip is faulty, coded incorrectly or not connected you will get a black and white chequerboard screen.

Now load up a game which is affected by the umbrella fault; in this case I loaded up Robocop 3 again.

Then wait…

…

…

And wait…

…

…

The 128k games take ages to load! This one took nearly 10 minutes! So glad I have the TZX Duino Amplifier fitted, I would have hated to get a tape loading error ;)

Game finally loaded.

And look, no raining effect! Job Done! Even Leo was impressed!

Youtube clip of the entire process is shown below

Well, I have had so much fun doing this repair; it is always good to get to use tools or equipment which I don’t usually use such as my Eprom programmer.

Many thanks to the clever folks at velesoft.speccy.cz for making their modification public.

This repair was easy on paper but a lot of care should be taken when removing the old HAL chip. It is very easy to damage the PCB traces on your +2, my rookie mistake was not to check the soldering on the component side correctly before removing the HAL chip. My only defence is that I checked that all the pins were loose on the solder side and gave the component side a quick look over before removing the IC.

Anyway, I hope that you found this entry useful; If you have any questions or queries about this fix, please feel free to leave a comment or email me directly at

Many thanks for taking the time to read this long entry.

Alleged-Geek

- Get link

- X

- Other Apps

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

Comments

Post a Comment