Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

ZX81 Composite Video Mod and internal 16K Ram Mod - Part 1

Populating the Composite Video Mod PCB

Following on from the success of the video modification I did to the ZX81 won at auction, I decided to do the same to my original ZX81. As this is my second ZX81, I decided to have more fun with it as well and install an internal 16k Ram chip. Both modifications are fully reversible and no destructive modifications are done to either the circuit board or the computer casing.

This entry will go into more detail about the video mod and will include a parts list, PCB designs (which can be found on my Github site) as well as a component by component population of the video modification PCB. I will also add a video of the whole process at the bottom of this entry.

So let’s make a start

The Composite Video Modification.

I would like to thank JoulesperCoulomb from zx.zigg.net for supplying the schematic for the circuit.

You can find information about it on

zx.zigg.net

Here is the direct link to the documentation

http://zx.zigg.net/misc-projects/ZX81_Video_Conditioning.pdf

and below is a pretty in depth explanation of how the circuit works on youtube

https://www.youtube.com/watch?v=1irH3KuGyl0&t=0s

Although the original PCB I designed worked flawlessly, I decided to tweak the design a little and order some circuit boards from JLPCB as I wanted a professional finish to the circuit board.

Below are the pictures of my updated design.

The above schematic is actually MK3 PCB, in this schematic I added C5 in parallel with C3 as I was having trouble finding 820pF ceramic disc capacitors. I actually ended up using a 680PF and a 220pF which when put in parallel gave me 900pF (I really need to replenish my ceramic capacitors stock) a 680 and 150pF would have been the ideal choice!

Below is a picture of my Eagle board layout

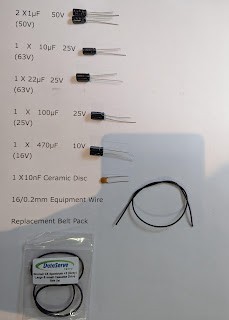

Below is a parts list and ordering information from www.rapidonline for the circuit board (There are enough components for five circuit boards as the minimum order of PCB’s from JLPCB is 5

10 X 81-0256 - CDIL 2N2222A NPN Transistor General Purpose RF

@ £0.457 each

5 X 11-0230 - Forever RB 22U 25V 85°C Radial Lead Aluminium Electrolytic Capacitor @ £0.041 each

10 X 73-0077 - Royal Ohm CFR01SJ0103A10 10K 5% 1W Axial Carbon Film Resistor @ £0.098 each

5 X 73-0062 - Royal Ohm CFR01SJ0680A10 68R 5% 1W Axial Carbon Film Resistor @ £0.098 each

5 X 73-0114 - Royal Ohm CFR01SJ0560A10 56R 5% 1W Axial Carbon Film Resistor @ £0.098 each

100 X 47-3416 - DC Components 1N4148 Signal Diode 75V 150mA

@ 0.0152 each (minimum quantity is 100)

5 X 11-3406 - Kemet R82EC2100AA50K 10nf 10% 100V 5mm Polyester Box Capacitor @ £0.068 each

10 X 11-3407 - Suntan TS170R2A820JSBNA0R 82pF 5% 100V NPO P:2.54mm Radial Ceramic Capacitor@ £0.052 each

10 X 11-3433 - Suntan TS170R2A471JSBNA0R 470pF 5% 100V NPO P:2.54mm Radial Ceramic Capacitor@ £0.091 each

10 X 11-3432 - Suntan TS170R2A331JSBNA0R 330pF 5% 100V NPO P:2.54mm Radial Ceramic Capacitor@ £0.095 each

5 X 82-0336 - Texas Instruments NE555P Bipolar Single Timer

@ £0.44 each

Grand Total cost for components = £13.18

There will be shipping on top of the above price so it may be cheaper to buy from ebay.

Eagle PCB files, Gerber files for JLPCB and components list and order codes available on my Github site

https://github.com/Alleged-Geek/ZX81-Composite-Video-Mod

Feel free to use my design (or modify it should you wish) All you have to do is upload the zip file

to JLPCB and then you will get the following images from their gerber viewer

This is an image of the component side which has all the values and relevant information printed as a part of the silkscreen

Below is an image of the solder side

After a couple of weeks, the circuit boards should turn up and look something like this

Note that there is only one space for a capacitor on the bottom right of the PCB; I redesigned the board so that you can put two capacitors in parallel to get the required value of 820pF.

Now let’s have a look at the actual components and tooling required to do this mod.

Before soldering please ensure that you are wearing suitable PPE; I recommend safety glasses and a well ventilated room.

To make things easier for you when soldering, start with the smallest (in height) components then populate up to the tallest component last.

Pick up one of the 1N4148 signal diodes then bend the legs at 90° as shown in the picture below

The black stripe on the diode indicates that,

that is the cathode side of the diode; it is important that you get this the

right way round in the circuit. Below is a picture of the correct positioning

of the first signal diode.

Holding the diode flat against the component side, turn the PCB over then bend each leg out by around 45° (this prevents the component from slipping down from the component side)

Then solder each leg

When soldering, place the very tip of your soldering iron on to both the component leg and silver pad (via) to heat up the parts so that they are both warm enough to melt solder; I recommend about 3 seconds, then feed the solder on to the opposite side of the tip of your soldering iron and component leg and it should simply melt.

It is worth noting that too much solder will result in a blobby solder joint and too little could result in gaps between the component leg and via.

What you are looking for is a nice curve (all the way round) up from the via to the component leg. Once you have fed enough solder on to the joint, remove the solder whilst keeping the soldering iron on the component leg and via (for 2 – 3 seconds) then quickly remove the tip from the solder joint. If you remove it slowly you could end up with a jagged edge on your solder joint.

Using your cutters, trim both of the surplus component legs off the circuit board. Try to trim the legs just above where the solder stops as cutting into the solder will result in a weak solder joint.

Now pick up D2 and bend the legs as before with your pliers

The cathode of D2 is facing towards the middle of the circuit board as shown below

It is the same soldering process; press the diode flat against the component side, bend the legs out 45°, solder then trim

Now pick up R1 which is a 10kΩ resistor

The colour codes are Brown, Black, Orange, Gold

And place it in the R1 position on the circuit board; it does not matter which way round the resister goes but I like all the gold bands to face the same way which makes it easier for me to read the values of the resistors in circuit.

Now solder and trim the legs

R2 is next and that is another 10kΩ resistor (Brown, Black, Orange, Gold)

Place it on the circuit board then solder

R3 is a 68Ω (68r) resistor and the colour codes for that is (Blue, Grey, Brown, Gold)

Place it in the circuit then solder

The last resistor is a 56Ω (56r) and the colour codes for that are (Green, Blue, Brown, Gold) place it in the circuit then solder.

Next up is the 82pF ceramic disc capacitor; for this type of capacitor it does not matter which way round it is soldered into the circuit but I like to place it so that I can easily read the value printed on it in this case the 82pF capacitor is C4 so I soldered it in place with the writing pointing outside the circuit board.

For placement, it is the same as the diodes and resistors; try and get it as flat against the component side of the PCB as possible, bend the legs out by 45° then solder.

Below is a picture of the actual component with markings (82)

Which tells me that it is in fact an 82pF capacitor

Now solder it into the circuit then trim the legs.

Now we come to a tricky part; I couldn’t find an 820pF capacitor from my supplier so I had to improvise. What I ended up doing here was to solder two capacitors in parallel which will be easier in the PCB design I have uploaded to Github as there is space for two capacitors. What I ended up doing was to solder another capacitor on the vias of C3 on the solder side of the PCB.

I looked for the two values I recommended earlier but didn’t have them in stock so I opted to use 220 and 680pF capacitors in parallel, simply add the numbers together and that will give you the new value of the capacitor in this case it will be 900pF (a wee bit high but it should still work ok)

Look at the markings on the picture below although very faint it says that it is a 221 capacitor which means that it is a 220pF capacitor.

Like the other ceramic disc capacitor, it does not matter which way this goes round on the circuit board but again, I like to be able to read the values once soldered on to the circuit board so I opted to have the printed value facing outwards as you can hopefully see in the picture below.

And here is a top view of the capacitor soldered into the circuit.

Now for the tricky part; soldering the other C3 in parallel. For this capacitor I am using a 680pF capacitor which has the markings 680 on it as you can see in the picture below. Isn’t it strange that some manufacturers put the actual value of the capacitor on and some use the capacitor value code like the 220pF capacitor above?

Bend the legs out 90° as shown below.

Now we want to solder the capacitor on the solder side of the circuit board on the same via’s (pads) as the ones we have just soldered C3 (220pF) on to. Place the capacitor on the circuit board as shown below.

I then tinned the legs (added solder) of the capacitor at the bend on each leg which will make soldering a lot easier then solder one leg on to one of the via’s.

Now solder one of the legs on to either of the via’s; again note that I have opted to have the printed value visible.

Solder the second leg on to the other via then carefully trim the legs of the capacitor.

Now we are going to solder in the IC socket for the 8 pin 555 Timer chip. If you look closely at the socket, you will notice a notch cut out of the plastic in the middle of the plastic housing; this tells you that pin 1 is to the top left hand side of the socket.

It is really important to solder this in the correct way as placing the 555 timer chip in the wrong way round will almost certainly destroy the chip when powered up. It is also worth noting that you do not necessarily need to use a socket and you can solder the chip directly on to the circuit board.

Now let’s have a look at the PCB; highlighted is the silkscreen outline of the 555 chip and the corresponding notch.

Place the socket on to the PCB then turn the PCB over to solder. A wee tip here is to solder opposite corner pins then check if the IC socket is lying flat against the component side of the PCB. If not, simply hold the IC socket with your finger, heat the corner pin which may be raised with your soldering iron then push the IC socket until it is lying flat.

Once happy that the socket is seated correctly, solder the remaining pins

The next components to be soldered are Q1 and Q2; they are 2N2222 NPN transistors. There are three pins on these components, a Collector, Base and Emitter. The emitter can be found by the tag highlighted in the pictures below.

Below is a picture of the underside of the 2N2222; I have highlighted the emitter tag

Place the component into the circuit; a wee note here, don’t push the component flat against the PCB, and ensure that there is about 5 mm clearance from the component side to the bottom part of the aluminium casing of the transistor. Then solder the transistor in place.

Do the same for the second transistor but note that the emitter tag has been rotated 90° clockwise.

Now place C2 into the circuit; this is a 10nF capacitor. It has the markings 10n K 100; the 10n means that it is a 10nF capacitor, the K is the tolerance and the 100 is the maximum voltage.

It does not matter which way round this goes but I like to have it placed so that I can read the value easily so I placed it with the text reading the same way as the silkscreen writing on the PCB.

Place it into the circuit then solder; again ensure that it is seated flat against the component side of the PCB.

Now we come to the final component to solder and arguably the most dangerous one as if fitted incorrectly it could explode when powered up!

C1 is a 22uF electrolytic capacitor; it is polarity conscious meaning it has positive and a negative legs. The easy way to determine which leg is which is that when new, the longer leg is almost certainly the positive leg. If you follow the shorter leg up to the component, you will see markings along the side of the capacitor which should have a minus (-) sign.

I have highlighted the positive leg. The markings on this capacitor are 22uF 25V, this means that it is a 22uF capacitor with a maximum working voltage of 25V. Any 22uF capacitor with a working voltage of 5V or greater will work with this circuit but as the voltage increases, so will the physical size of the capacitor.

Place the capacitor with the positive leg (longer one) in the via highlighted below.

Then solder the capacitor into the circuit

Looking from the side, you should see that the negative side of the capacitor is facing the IC socket.

Now we are going to solder the wires directly on to the circuit board; I could have used header pins for this but there is little advantage in that and it would increase the cost of the circuit board (and you know how painful that is for Scotsmen and in particular Aberdonian Scotsmen ;o))

Firstly we need to prepare the wires for soldering.

Cut four wires to length, I think I used about 150mm (it is always best to have the wires too long) then strip about 10mm of the insulation off one end of each wire.

Below is a picture of the tools and wire needed for this part.

I used 7/0.2mm equipment wire for this so to strip the insulation off the wire, I used the 0.6 hole in my wire strippers. It is easy to cut the actual wire when doing this so a good tip is to start with a larger hole in your wire strippers and see if it removes the insulation; if it doesn’t then go to the next smallest hole and try again.

Twist the frayed wires together tightly

Then tin the end of the wire (coat it with solder) this will ensure that the wire doesn’t fray when putting it through the Via and it will also make it much easier to solder.

There are a few ways to tin the end but the safest way is to use some helping hands; hold the wire in the clip, take the tip of the soldering iron up to the insulation, then add solder whilst running the iron along the exposed wire until the end (continually feeding solder as you do so)

You will have excess solder on your soldering iron at this point so it is a good idea to wipe the excess solder off using the sponge or tip cleaner afterwards.

now place the wires into the circuit.

For the 5V Via I used red wire

For the Input Video Via I used white wire

For the 0V Via I used black wire

And for the Output Video I used yellow wire

Let’s start with the 5V wire; the via is situated on the top left of the circuit board.

Turn the board upside down and bend the tinned wire to about 45°. Then solder.

Then repeat for the remaining wires. Below is a picture of all four wires soldered into place. Please note that there is no exposed wire showing from the component side upwards. If you do have any exposed wire, heat the via up with the soldering iron until the solder melts then gently push the wire up until the insulation of the wire touches the circuit board.

Here is a side view of the circuit board which shows that there is no exposed wiring showing.

Now all we have to do is to fit the 555 timer IC. I tend to keep most of my IC's in a static sensitive box but you should be ok with the 555 timer as it isn’t really static sensitive.

When new, the legs of the 555 timer are spread out too wide to fit into the socket so we need to straighten the legs. There are a couple of ways to do this; I am lucky enough to have an IC leg straightener so I simply run the IC along the track and through the bearings which straighten the legs beautifully.

The other way to do this without the expensive leg straightening tool is to simply place the IC on its side (as shown in the picture below) and rock the IC until the legs are straight. Don’t use too much force doing this as you could over bend the legs and if you are unlucky, you could even break the ends of the legs off the IC.

Now let’s take a look at the IC itself; I have highlighted the notch on the IC. This tells us that pin 1 is to the top left hand side of the IC. Pin 2 is directly below pin 1 and the pins count in a counter clockwise direction with pins 1 (top left) – 4 (bottom left) being on the left hand side and pins 5 (bottom right) to pin 8 (top right) being on the right hand side.

Highlighted below is the position of the notch on the IC socket on the circuit board.

Finally fit the 555 Timer chip into the circuit.

And here we have a fully populated circuit board.

A video of the population of this circuit board can be found below

All we have to do now is to fit it into the ZX81 which will be coming up in part 2 of this thread.

I hope that you have found this entry interesting; I decided to go into more detail about the actual soldering of the circuit board for this entry as I thought that my last one didn’t cover that part of the mod enough. You may decide to use another circuit board for this mod which is fully populated but I have included everything that you will need to make the PCB featured in this entry.

You will find all the files on my Github

https://github.com/Alleged-Geek/ZX81-Composite-Video-Mod

If you have any questions or queries about this circuit board then please feel free to get in touch either through the blog or by email

Thank you for taking the time to read this entry

- Get link

- X

- Other Apps

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

Comments

Post a Comment