Search This Blog

Repair and restoration of retro consoles, 8 bit computers. In this blog I hope to show you how to repair, retrore and modify old consoles and handhelds, from manufacturers such as Atari Amstrad Acorn Sinclair Commodore Dragon Sony MSX BBC Playstation Sega Microsoft xbox Spectrum ZX81 Vic 20 VIC20 C64 Amiga Binatone Grandstand.

Featured

- Get link

- X

- Other Apps

Commodore Vic 20 (the 3 R's) Repair, Restore and Retrobrite

This is my most ambitious blog entry yet; I decided to record the work done on this Vic 20 on video as well as post pictures and clips on this blog. I am still finding my feet so bear with me, all comments good or bad would be extremely beneficial.

Now, living

in Scotland, it is unusual to get a whole lot of sunny days (even less frequent when you have a day off work) so when I looked

out of the window at silly o'clock yesterday morning and saw a beautiful blue sky, I hatched my geeky plan... I was going to repair, restore and retrobrite my new Vic 20!

Time to get working!

Here is the Vic 20 as bought at auction on ebay

Not too bad,

it has its original box, granted bit battered

Original Polystyrene packing

Original data recorder (filthy)

A original game

And an Atari Joystick

According to the ebay listing, the only thing wrong with the machine was the fact that the X key did not work.

That shouldn’t be too much of a problem, what I really wanted to do was to retrobrite the machine. A nice sunny day in Aberdeen, a day off work, perfect conditions for some geekery!

I am going to post a step by step process of the complete job; adding more hints and tips than I could on the youtube clip.

Lets get the machine through to my Geek room

Firstly, we need to get inside the thing, highlighted in the photo below is the location of the three fixing screws.

Remove the screws with a medium pozi drive screwdriver and place somewhere safe (I used my magnetic work mat)

Here is a picture of the inside

Lets get the lid off now

Unplug the LED connector

Then unplug the keyboard connector

Straightforward so far

Time to get the motherboard out

Highlighted in the photo below are the fixing screw locations for the motherboard. Again a medium sized pozi screwdriver works well. There are 9 screws to remove.

Now, I want to inspect the motherboard, firstly the component side

A wee bit dusty and grimy but everything looks in order, no leakages from any of the capacitors and the soldering looks good from above. You could use compressed air to blow away the dust or use an aerosol air duster but I opted to use a good old fashioned paintbrush and tidied up the whole layer with 99.9% Isopropyl Alcohol and cotton buds.

Now for the solder side

A couple of things stood out straight away. As can be seen on the next couple of photographs, there was flux residue around two connectors and a capacitor. This was suspicious and I decided to clean the area with some Isopropyl and Mrs Geeks toothbrush.

The youtube clip at the end contains a speeded up version of that process.

Further inspecting the soldering on the motherboard, I came across two suspicious solder joints on the keyboard connector, I have highlighted the two joints in the photo below. It isn’t the best photo in the world but they were a bit duller than the rest and it appeared like someone had worked on them before. There was also some flux residue around both joints. Suspect dry joint?

In the end, I decided to desolder both solder joints then resolder them, cleaning away any excess flux with isopropyl alcohol afterwards. Again the youtube clip shows this process.

Then I cleaned up the gold plated edge connector with isopropyl alcohol and a few cotton buds. A wee note here: do not use an abrasive cleaner such as metal polish as this will remove the very thin gold coating on the edge connector. If you don’t have isopropyl alcohol a simple eraser should clean the gold plated traces up nicely. The whole process was recorded for the youtube clip.

Happy with the motherboard, I decided to turn my attention to the keyboard. This has a known fault with the X key. Time to find out which version of keyboard I have; the one with the springs like my C64C or the one with the bubble connectors.

Firstly I had to remove the keys from the keyboard. There are a number of options here, you could either

use a professional key removal tool

or

carefully use a flat bladed screwdriver or pudger to lever the keys off

but

I decided to use brute force and ignorance and pulled them off with my hands as the youtube clip shows.

Before we can get inside the keyboard, we have to remove the yellow wired from the Shift Lock key

Highlighted below is the two wires we have to desolder

The whole practice is shown on the youtube clip, but basically, I freshened up the solder then reflowed the solder and gently pulled the wires off the legs of the switch. However, care must be taken not to burn your fingers doing this so if you are unsure, please use tweezers or pliers to lift the wires off the legs of the switch.

The next thing to do is open up the keyboard.

Below are the locations of the 19... yes 19! Small screws which have to be removed before opening up the keyboard to see what lies beneath. You will need a small pozi drive screwdriver to remove these screws (again store them away safely)

Once opened I found out which version of keyboard I had...

It was the one with the bubble connectors. The rubber used for the spring effect can perish and grow brittle with age so care should be taken when removing them. The picture below shows you what I found inside the keyboard.

I stripped all the bubble connectors off the PCB and placed them in a separate container, I then removed all the key posts and put them in another container for cleaning.

Remove the Shift Lock key by pushing firmly down on the switch from the inside part of the keyboard housing (see video)

As I mentioned earlier, there was a known issue with the X key, time to investigate the keyboard PCB...

Some of the contacts were a wee bit tarnished so again I attacked it with isopropyl alcohol and a lint free wipe (see video) and I soon had a sparkling clean keyboard PCB.

Now for the bit I was dreading... the filthy Data Recorder!

Remove the four screws with a medium sized poi drive screwdriver, see picture below for location

Look at the mess of the bottom half of the data recorder! Yukk!!

After that, the tape drive unit should just lift out

Time to clean up the data recorder unt.

I used a soft paintbrush to remove all the dust and loose dirt, then again with the isopropyl alcohol and cotton buds I cleaned up the unit the best I could (see video) I even cleaned the tape heads with some isopropyl alcohol and a clean cotton bud.

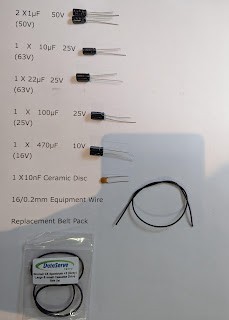

The drive belts all looked to be in good condition but they are easily available on ebay should they be perished, loose or broken, thankfully I didn’t have to wait (don’t you just hate having to wait for replacement parts? Yet again another wonderful geek trait ;o) )

With everything stripped down, it was time for the retrobriting, here is a picture of all the striped down Vic 20

For the retrobrite process you will need the following supplies

Cream Peroxide (40%)

Cling Film Wrapping

Paint brush

Toothbrush

Foam based scouring pad

Washing liquid

Wooden skewer or pointy spudger (for awkward dirt in hard places to reach)

Container for the Cream Peroxide

Most of the process is shown on the video but I will try and go through the process in a simplified form through text.

Cleaning the components

I use washing liquid and a toothbrush to clean each part thoroughly

Failing to clean the dirt off more than likely result in darker patches appearing on the plastic of the plastic being retrobrited.

For awkward parts, such as text on the plastic or nooks and crannies, I use a wooden skewer (using anything harder will result in scratching the plastic)

For stubborn stains or scratches, you can use a foam based scouring pad to gently buff out the marks. One word of advice here is not to rub too hard as this will result in scratching the plastic.

Rinse thoroughly and dry off completely (as not to dilute the cream peroxide when applying it)

Applying the Cream Peroxide (40%)

Safety first...

If not wearing glasses, use a pair of safety glasses... your eyes are important to you, don’t scrimp for the sake of a couple of quid. If this stuff gets into your eyes it can be quite harmful!

and

Wear gloves!

Cream peroxide kind of burns and you will be left with a lovely white stain on your fingers as I found out!

Measure the part being retrobrited, then lay out cling film wrapping so that it is at least 60% wider on each side.

Apply the cream peroxide with a paintbrush (try to have an even coat of cream peroxide on each surface as the cream peroxide will lighten the areas more where there is more cream peroxide, leaving you with a streaky kind of finish)

Once done, seal up the part with the clingfilm wrapping. The cream peroxide will heat up in the sun and kind of ‘boil and steam’ (not extremely hot but warmer than the outside temperature) if there are any leaks this will dampen the effects of the retrobrite.

The only other thing I advise you do is to place your keyboard keys on a moveable surface (I used a glass chopping board in this instance) if you simply have the keys on a clingfiilm wrapping base they it will fall apart when moving. The rigid plate ensures that you can move the keys without issue (ant it also makes it easier to rotate in the sun).

Exposing the parts to UV from the sun.

Place parts in a sunny part of the garden (the sun hits my back garden from around 10am – 4pm)

Keep checking regularly (around every hour)

Rotate each part 90 degrees during these checks

Rub all the surfaces of each part to ensure that the cream peroxide doesn’t dry out; this also puts a fresh coat of cream peroxide on each surface. Failing to do so could result in a streaky finish. Don’t despair if that happens as you can go through the whole process from start to finish until it is squeaky clean.

I leave my parts out in the sun for around 6 hours then take them in for cleaning and drying.

Cleaning and drying the parts after the retrobriting process.

Basically this is exactly the same as preparing the parts for retrobtiting, rinse, wash then rinse again. The only difference being is that you should be wearing safety gloves and glasses during this process.

Particular attention should be paid to nooks, crannies, hard to get at places, bosses for fixing screws and fixing screw holes. What tends to happen there is that the cream peroxide will not wash away completely. Use cotton buds and wooden skewers to ensure that no cream peroxide is left after washing.

Dry the parts off completely before assembly.

Use paper towels to dry the parts off as best you can

For hard to reach areas, use cotton buds or wooden skewers and paper

Then as a final ‘make-safe’ leave each part out in the sun for around an hour.

Reassembly

Starting with the keyboard

Insert the Shift Lock key (the reverse process of removal) push the switch firmly up from the outside, you will hear a click if this is done successfully.

Place the keyboard on some kind of stand; this raises the keyboard allowing the key posts to seat correctly in their slots. In this case I used two dreamcast games either side of the keyboard (see photo below)

Insert the keyposts as shown in the photo above

Now fit all the ‘bubble connectors’ as shown in the photo below; again ensure that they are all seated correctly as if not it could result in non-functional keys.

Fit the Keyboard PCB and screw in all of the 19!! Small screws... 19!!!

Nearly there, solder the yellow wires on to the legs of the Shift Lock switch

Starting with the spacebar (because it is awkward and you may need space either side for fitting) fit all the keys to the keyboard... can you remember where they go? ;0)

Now you should have a beautiful looking keyboard!

Screw the keyboard on to the lid of the Vic 20 using the 8 screws shown in the photo below

Fit the LED; this is a push fit into an LED holder so it should stay (if it is a bit loose and want’s to fall out then as a last resort, use hot melt glue... never ever thought that I would say that!!!)

And here we have a fully populated lid

Now for the bottom part

Remember to fit the bezel/faceplate before fixing the motherboard

Fix the motherboard using the 9 medium screws as before

Fit the LED connector as before

Fit the keyboard connector as before

And this is what it should look like

Screw the main fixing screws to the Vic 20 as before

Now it comes to the serial number label which fell off during cleaning.

Clean the ‘sticky side’ with isopropyl alcohol to remove the old glue

Use double sided sellotape and attatch it to the glue side of the label; I have some extra wide tape which is ideal for this (if you have a slimmer tape, then try and cover as much of the label as possible without double layering the tape)

Use a scalpel or trimming knife to cut around the outside of the label. Please note that scalpels are extremely sharp... watch those fingers! Use a chopping board if possible to avoid any scratches on your work surface

Vic 20 fully assembled, we can now turn out attention to the data recorder.

Fit the cassette carrier back on to the top part.

Fit the cassette drive to the top part

Fit the main fixing screws as shown earlier

Now everything is reassembled…

Time to be nervous…

Will it work…

Wire it all up…

Cross your fingers, hope for the best, close your eyes as you switch it on…

And…

And…

Success!

The Vic 20 lives!

All keys now functional and it loaded up a game from the Data Recorder!!!

Job Done!

Here are some before and after pics

Before

After

I have had sooo much fun doing this restoration and it only took me a day!

Here is the youtube clip featuring all of the above drivel in just over 30 minutes

If you have any questions or queries about this restoration then as ususal, please feel free to email me at

Thank you very much for taking the time to read this entry.

- Get link

- X

- Other Apps

Popular Posts

ZX Spectrum +2 (grey) Cassette Drive Overhaul, Repair and Restoration

- Get link

- X

- Other Apps

Comments

Post a Comment